Why Small-Scale Environmental Tanks Are Essential for Spill Control

Reliable containment solutions are crucial for handling dangerous substances and stopping environmental damage. Of these options for small-scale spill management,...

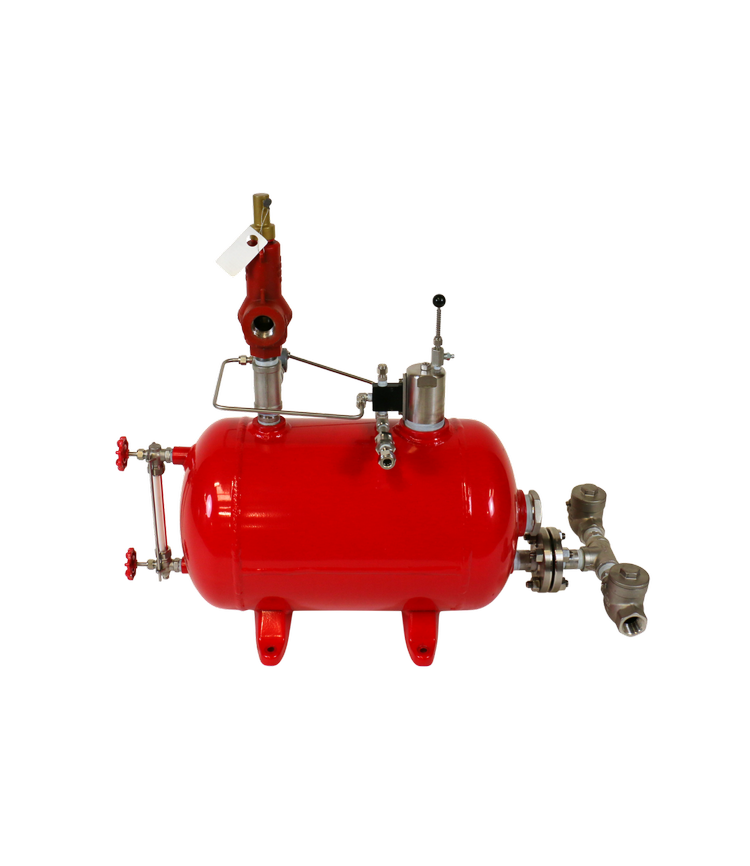

Reliable containment solutions are crucial for handling dangerous substances and stopping environmental damage. Of these options for small-scale spill management, the 10 gallon environmental tank is both sensible and effective. Before they seriously affect the environment or regulatory compliance problems, these small tanks give companies and facilities a means to properly store, control, and contain possible leaks. This article investigates why small-scale environmental tanks are vital instruments in spill prevention plans, stressing their advantages, pragmatic uses, and how including cutting-edge technology like A-Frame BTEX Systems might improve spill control initiatives.

The Value of Controlling Spills for Environmental Protection

Whether fuel, chemicals, or industrial fluids, spills of hazardous liquids seriously compromise soil, water, and air quality. Unchecked discharges can cause expensive clean-ups, fines, and major harm to public health and ecosystems. Preventing these results and guaranteeing that companies run within environmental rules depend on efficient spill control.

For handling lower volumes of possibly hazardous products, small-scale environmental tanks—like the 10-gallon environmental tank—offer an easily available and controlled alternative. These tanks offer a safe confinement space that reduces the possibility of leaks and spills under storage, transfer, or emergency containment plans. Facilities can lower their environmental impact and increase general safety by tackling spill management on a reasonable level.

Features of a 10-Gallon Environmental Tank

The adaptability of a 10-gallon environmental tank is one of the benefits. These tanks fit many different sectors and uses; small enough to fit in confined areas but big enough to contain a lot of fluid. From labs and factories to auto shops and building sites, they offer consistent containment where bigger tanks might be unneeded or impossible.

Furthermore ensuring long-term usability are generally sturdy materials resistant to corrosion, solvents, and UV damage in which these tanks are built. Many variants include lockable lids and fittings to stop inadvertent spills during transportation or storage as well as secondary containment devices to catch leaks before they escape.

These tanks’ mobility lets one be flexible in dynamic work conditions and easily move to where containment is most needed. Furthermore, their reasonable size indicates they need less room and upkeep than bulk storage tanks, which helps small-scale spill control to be more affordable.

Small-Scale Environmental Tanks: Applied Scenarios

In many real-world applications, small-scale environmental tanks are essential. In fuel dispensing stations, for instance, a 10-gallon environmental tank can act as an emergency spill reservoir to catch any inadvertent hose or pump overflow. These tanks give a safe place in chemical laboratories to temporarily store dangerous waste before appropriate disposal. They can be used on building sites to hold solvents or oils used there, therefore preventing leakage into nearby rivers or soil.

Many times, these tanks are part of a larger strategy for spill avoidance, including absorbent materials, spill kits, and routine inspections. Facilities build a layered defense against environmental pollution by combining additional safety precautions with small-scale tanks.

Improving Control of Spill Using A-Frame BTEX Systems

Integrating cutting-edge technologies like A-Frame BTEX Systems as spill control technology develops will greatly increase the efficacy of environmental tanks. Benzene, Toluene, Ethylbenzene, and Xylene, or BTEX for short, are volatile organic chemicals frequently found in petroleum products that damage the environment as well as human health.

Designed to catch and treat vapors emitted during fuel handling and storage, A-Frame BTEX Systems lower dangerous emissions and improve regulatory compliance. These devices offer a double method of spill control—physical containment of liquid spills and control of vapor emissions—when coupled with a 10-gallon environmental tank.

In sectors including fuels and solvents, where the risk of both liquid and vapor emission is great, this mix is very helpful. Using A-Frame BTEX Systems alongside environmental tanks helps buildings show environmental stewardship, preserve air quality, and keep safer workplaces.

Environmental Responsibility and Regulatory Compliance

Using small-scale environmental tanks, such as the 10-gallon environmental tank, fits the rising regulatory needs for environmental protection and spill avoidance. Businesses handling hazardous materials might have to comply with strict spill control policies, including secondary containment and vapor control, depending on environmental regulators.

Ignoring rules could lead to large penalties, repair expenses, and a company’s reputation suffering. Conversely, making appropriate investments in containment tools shows a dedication to environmental preservation and community safety. It fosters public confidence as well as customer and regulatory trust.

Environmental Tanks’ Maintenance and Best Practices

Regular maintenance and following top standards are crucial if one wants to fully enjoy small-scale environmental tanks. This covers regular leak, crack, or corrosion checks; timely cleaning to prevent hazardous residue accumulation; and verifying that all lids and fittings are tight.

Preventing spills also depends critically on staff members receiving appropriate instruction on handling and emergency response protocols concerning the tanks. Moreover, keeping precise records of tank use and inspections helps compliance audits and ongoing environmental safety program enhancement.

Summary

For many different kinds of businesses, small-scale environmental tanks such as the 10 gallon environmental tank provide an absolutely essential means of spill management. Their small scale, robustness, and adaptability make them perfect for securely storing dangerous liquids and stopping environmental damage.

Combining modern technology like A-Frame BTEX Systems with these tanks addresses both liquid containment and vapor emissions, therefore offering complete spill protection. Investing in these systems not only helps facilities follow strict rules but also safeguards public health and helps to preserve natural resources.

Small-scale environmental tanks are ultimately a proactive approach toward responsible environmental management, risk reduction, and sustainable company operations. Any business handling hazardous chemicals should make sure its spill control plan includes these tanks first.