What Is AVEVA Edge and Why Is It Useful for Modern Industries?

The world of industrial automation is always changing, and businesses are looking for ways to stay ahead. One powerful solution...

The world of industrial automation is always changing, and businesses are looking for ways to stay ahead. One powerful solution that’s making a difference is AVEVA Edge. In this article, we’ll explain what AVEVA Edge is, how it works, and why companies across the globe trust it to make their operations smoother, safer, and more cost-effective. You’ll also find practical tips, facts, and examples showing how this technology is shaping smart factories for the future.

Understanding AVEVA Edge

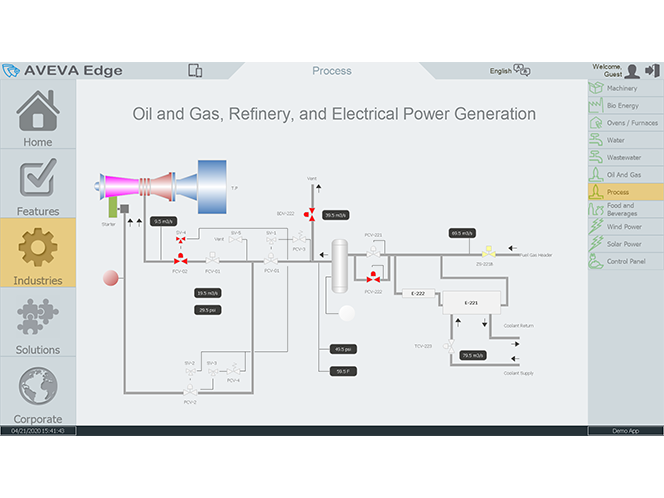

AVEVA Edge is a flexible HMI and SCADA software platform designed for industrial PCs and edge devices. The platform lets users build real-time dashboards, control systems, and remote monitoring solutions without heavy hardware requirements. This makes it easy to connect machines, sensors, and data sources, even in environments with limited resources or no full-time IT staff.

Developed by AVEVA, a leader in industrial software, AVEVA Edge supports multiple operating systems, including Windows and Linux. It’s used by manufacturers, utilities, water treatment plants, energy providers, and many others looking for reliable automation tools.

Why Modern Industries Need AVEVA Edge

Modern industries face challenges like rising costs, strict regulations, and the push for higher productivity. AVEVA Edge gives companies a way to meet these demands without huge upfront investments. By making it easier to automate processes and gather real-time data, AVEVA Edge helps organizations:

- Reduce downtime and boost output

- Catch problems early before they become expensive

- Track energy use, waste, and other key metrics

- Improve workplace safety and compliance

- Adapt quickly as needs change

According to recent studies, companies using HMI SCADA software have seen up to 25% reductions in unscheduled downtime and up to 15% improvements in energy efficiency.

How AVEVA Edge Works

At its core, AVEVA Edge acts as a digital control center. It brings together information from different devices—like sensors, pumps, and conveyor belts—and lets operators view, control, and analyze everything from a single dashboard. The platform supports real-time monitoring, so problems are spotted instantly and can be fixed faster.

Because AVEVA Edge runs on both small embedded devices and full-scale PCs, it’s perfect for factories with equipment from different eras. Its flexible design means you can start small and grow as your business does. With support for mobile devices, remote teams can keep track of systems from anywhere.

Key Features of AVEVA Edge

- Easy-to-Build Dashboards: Drag-and-drop tools let users create custom screens for different roles—no coding skills needed.

- Open Connectivity: Connects easily with PLCs, IoT sensors, databases, and other systems.

- Security: Built-in user authentication and encrypted communications keep data safe.

- Alarming and Notifications: Sends alerts by text, email, or mobile app when something goes wrong.

- Data Logging: Tracks trends and keeps historical records for compliance and analysis.

- Flexible Deployment: Works on industrial PCs, embedded systems, and cloud environments.

- Remote Access: Operators and managers can monitor and control systems from their phones, tablets, or laptops.

Use Cases for AVEVA Edge

Many industries use AVEVA Edge to boost efficiency and cut risks. Here are some real-world examples:

Manufacturing:

A parts supplier installed AVEVA Edge on their production line to monitor machine health. The system tracks temperature and vibration in real time, helping prevent costly breakdowns. After six months, the company reported a 20% drop in unplanned downtime.

Water Treatment:

A municipal water utility uses AVEVA Edge for SCADA control across remote sites. The software gathers pump data and sends alerts if levels drop or equipment fails. This quick response has helped the city maintain clean water delivery without interruptions.

Energy:

An independent solar power provider uses AVEVA Edge to monitor hundreds of panels across multiple locations. They track performance and detect faults before energy output drops, boosting efficiency and cutting maintenance costs.

AVEVA Edge and Industrial IoT

The move toward industrial IoT (Internet of Things) is driving major changes in automation. AVEVA Edge fits perfectly here, as it connects old and new machines, collects data, and helps teams make smart decisions faster. By turning raw numbers into easy-to-read reports and dashboards, it’s easier to see where improvements can be made.

Expert Opinions and Industry Trends

Experts agree that edge computing and HMI SCADA tools like AVEVA Edge are key for the future of smart factories. According to a report by MarketsandMarkets, the global SCADA market is expected to reach $15.2 billion by 2026, with much of that growth driven by demand for easy-to-use, connected solutions.

PIMA Industrial, a trusted AVEVA partner, has helped dozens of businesses in South India upgrade their automation with AVEVA Edge. Their clients have seen improvements in uptime, quality control, and reporting accuracy.

Pros and Cons of AVEVA Edge

Pros:

- User-friendly interface, even for non-technical staff

- Works on a wide range of devices and operating systems

- Scalable for small plants or large operations

- Reliable support from local partners like PIMA Industrial

Cons:

- Initial setup may require training

- Custom features can take time to develop

- Integration with older hardware may need extra configuration

Frequently Asked Questions

Who uses AVEVA Edge?

Manufacturers, utilities, food processors, energy providers, and more use AVEVA Edge to manage equipment and processes.

What does AVEVA Edge do?

It provides real-time monitoring, control, alarms, and analytics through easy-to-build dashboards and reports.

Where can I buy AVEVA Edge?

You can get it through authorized partners like PIMA Industrial, who offer sales, support, and training.

Why choose AVEVA Edge over other SCADA software?

It’s flexible, affordable, and works well with both modern and legacy equipment.

How is AVEVA Edge installed?

It can be installed on industrial PCs, embedded devices, or in the cloud, with guidance from certified partners.

Will AVEVA Edge work with my current machines?

Most likely yes—its open connectivity lets it talk to a wide range of hardware.

Getting Started with AVEVA Edge

If you’re interested in bringing AVEVA Edge to your operations, the first step is to speak with an expert. PIMA Industrial offers consultations and product demos to help you find the right setup for your needs. With their support, even small factories can achieve big results.

Conclusion

AVEVA Edge is changing the way industries manage automation and data. It’s simple to use, works almost anywhere, and helps businesses run better with fewer surprises. By partnering with experts like PIMA Industrial, you can move toward a smarter, safer, and more efficient operation. Don’t wait—contact PIMA Industrial today for a free consultation or share your thoughts in the comments below. Take the next step and make your factory work smarter, not harder.