Unlocking New Possibilities with Flexible PCB Innovations

In today’s fast-paced world of technology, innovation is key. One of the most revolutionary advancements in the electronics industry has...

In today’s fast-paced world of technology, innovation is key. One of the most revolutionary advancements in the electronics industry has been the development of Flexible Printed Circuit Boards (PCBs). These innovative solutions are enabling designers to think beyond the limitations of traditional rigid PCBs, creating new possibilities for a variety of industries. As a leading Flexible PCB manufacturer, we are excited to explore how these cutting-edge technologies are reshaping the landscape of electronics and driving future innovations.

What Are Flexible PCBs?

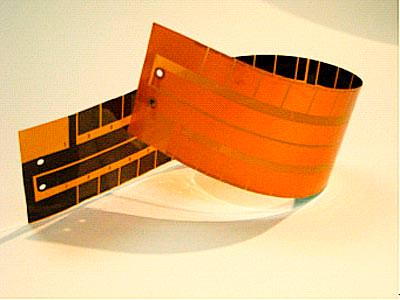

Flexible Printed Circuit Boards are a type of PCB that are designed to bend, twist, and flex without compromising their functionality. Unlike traditional rigid PCBs, which are made from solid substrates, flexible PCBs are constructed using flexible materials such as polyimide or polyester. This allows them to be used in applications where traditional rigid boards would fail due to space or design constraints.

Flexible PCBs offer a wide range of benefits, including reduced weight, space efficiency, and the ability to fit into unconventional shapes. These features are particularly valuable in industries like consumer electronics, automotive, aerospace, and medical devices. The flexibility and versatility of these boards are opening new doors for product design and functionality that were once thought to be impossible.

Key Advantages of Flexible PCBs

Space Efficiency and Weight Reduction

In industries such as automotive and aerospace, where every ounce and millimeter counts, the compact design of flexible PCBs is a game-changer. By reducing the need for bulky wiring and connectors, these boards allow for slimmer, more lightweight products. This is particularly useful in wearable devices like smartwatches or fitness trackers, where space constraints are crucial. With flexible PCBs, designers can maximize the use of available space while maintaining high performance.

Durability and Reliability

Flexible PCBs are not only light and compact, but they are also incredibly durable. They are less prone to damage from shock, vibration, or bending compared to their rigid counterparts. This makes them ideal for products that experience frequent movement, such as automotive electronics or portable consumer devices. Their resilience also extends to extreme temperature ranges, ensuring that they perform reliably in harsh environments.

Improved Signal Integrity

In electronic devices, signal quality is paramount. Flexible PCBs can help reduce signal interference and improve overall signal integrity. Their design allows for optimized routing of components, reducing the length of traces and minimizing the risk of electromagnetic interference. As a result, devices built with flexible PCBs often exhibit enhanced performance and more efficient power consumption.

Design Freedom and Innovation

One of the most significant advantages of flexible PCBs is the design freedom they offer. Engineers and designers no longer have to work within the limitations of rigid PCBs, which can restrict creativity. Flexible PCBs can be contoured to fit into irregular spaces and conform to complex geometries, allowing for more innovative and compact designs. This flexibility is particularly valuable in emerging fields such as the Internet of Things (IoT), where small, efficient devices are crucial.

Cost Efficiency in the Long Run

While the initial investment in flexible PCBs may be higher than traditional PCBs, the long-term savings are significant. Flexible PCBs can reduce the overall cost of production by eliminating the need for multiple assembly steps and connectors. Additionally, their durability means that products are less likely to fail prematurely, resulting in fewer warranty claims and lower repair costs.

Applications of Flexible PCBs

The versatility of flexible PCBs has led to their adoption in a wide range of applications. Some of the most notable industries benefiting from these innovations include:

- Consumer Electronics: Smart devices, smartphones, wearables, and other portable gadgets often rely on flexible PCBs to achieve slim, compact designs without sacrificing functionality.

- Automotive Industry: With the rise of electric vehicles (EVs) and autonomous driving technologies, flexible PCBs are increasingly used for sensors, cameras, and control systems that require high reliability and flexibility.

- Aerospace and Defense: Flexible PCBs are used in critical applications such as navigation systems, avionics, and satellite communications, where weight and space efficiency are of utmost importance.

- Medical Devices: Wearable health monitors, diagnostic equipment, and implantable devices all benefit from the small form factor and durability of flexible PCBs.

- IoT (Internet of Things): The proliferation of IoT devices, which require small, energy-efficient components, has driven demand for flexible PCB solutions that can meet the unique needs of this growing market.

Choosing the Right Flexible PCB Manufacturer

Selecting the right flexible PCB manufacturer is essential to ensure that your products meet the highest standards of performance and reliability. When evaluating manufacturers, it’s important to consider their experience in producing flexible PCBs, as well as their ability to handle the specific requirements of your project.

A reputable manufacturer should offer a range of customization options, including different material choices, thicknesses, and design capabilities. They should also have a robust quality control process to ensure that every PCB is tested for durability, functionality, and signal integrity.

Additionally, look for a manufacturer that offers excellent customer support and communication throughout the design and production process. Whether you’re working on a small-scale prototype or a large-scale production run, effective collaboration is key to achieving the best results.

The Future of Flexible PCBs

As technology continues to evolve, the demand for more compact, efficient, and flexible electronic components will only increase. Flexible PCBs are at the forefront of this transformation, enabling products to become smaller, lighter, and more functional. The future of flexible PCBs is bright, with potential applications extending far beyond what we can imagine today.

In the coming years, we can expect to see even more advanced flexible PCB technologies, including multi-layer designs, higher-density components, and even more robust materials. These innovations will continue to push the boundaries of what is possible, unlocking new possibilities for industries ranging from consumer electronics to aerospace.

If you’re ready to explore the potential of flexible PCBs for your next project, click this link here now to connect with a leading flexible PCB manufacturer and discover how we can help bring your ideas to life.

Conclusion

Flexible PCBs are unlocking a world of new possibilities for designers and engineers across a variety of industries. With their ability to reduce weight, improve performance, and provide design flexibility, these innovative solutions are transforming how we think about electronics. As a trusted Flexible PCB manufacturer, we are proud to be part of this exciting revolution and look forward to helping our clients unlock the full potential of their products.