Troubleshooting Common RazorGage Upcut Saw Issues in 2025

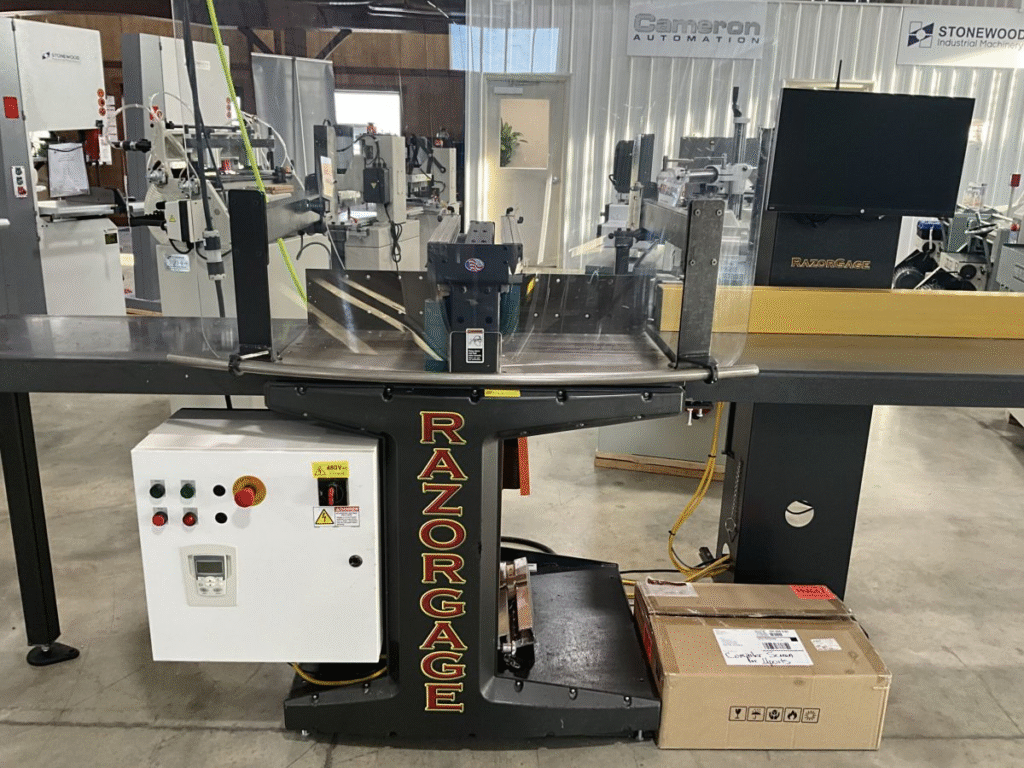

Optimizing Saws in 2025 requires staying ahead of both mechanical and virtual challenges. RazorGage Upcut Saw structures, known for his...

Optimizing Saws in 2025 requires staying ahead of both mechanical and virtual challenges. RazorGage Upcut Saw structures, known for his or her precision, can revel in diverse operational hiccups. Understanding and diagnosing those problems efficaciously ensures a smooth workflow and minimizes downtime whilst keeping safety and efficiency across reducing methods.

1. Understanding the Basics of RazorGage Upcut Saw Functionality

Before diving into particular troubles, it is crucial to comprehend how the RazorGage Upcut Saw operates. This present day saw gadget integrates CNC positioning and pneumatic upcut blades, taking into consideration automated and particular reducing. It is predicated on software program-guided automation, motor-driven components, and protection mechanisms to optimize productiveness. In 2025, more recent fashions have even tighter tolerances and more advanced managed units, which means troubleshooting calls for a more nuanced technique. Understanding the relationship among software instructions and mechanical actions is step one closer to diagnosing any hassle.

2. Diagnosing Power and Startup Failures

One of the most frequent issues pronounced with those saws is failure all through energy-up or startup. If the saw refuses to show on or initialize correctly, the basis purpose is often related to energy delivery inconsistencies, blown fuses, or defective circuit breakers. In a few instances, manipulated panels can also display mistakes codes indicating the supply of the trouble. Users should make sure that each power connection is steady and that voltage ranges meet the system’s necessities. If the RazorGage Upcut Saw does no longer respond in any respect, analyzing the emergency prevent button and protection interlocks should be the subsequent step, as those can save you startup if prompted.

3. Inconsistent or Inaccurate Cuts

Another common problem includes cuts which can be both inaccurate or inconsistent in period or angle. This problem commonly stems from positioning errors or issues with the servo motor that controls the measuring carriage. Misalignments, debris on the tune, or belt wear can all lead to cut inconsistencies. In 2025, the newest RazorGage Upcut Saws consist of self-calibration systems, however even these can fail if not well maintained. Regular inspections of mechanical additives, recalibrating sensors, and updating software programs are vital to restore unique operation.

4. Blade Jamming or Failure to Complete Cuts

Blade jamming or the noticed failing to complete a reduce is a mechanical difficulty that frequently relates to particle buildup, incorrect blade kind, or actuator failure. Since the upcut noticed design moves the blade upward via the material, obstructions under the workpiece or dull blades can without difficulty cause jams. In some cases, the air cylinders using the blade may also lose strain due to air leaks or malfunctioning valves. Proper lubrication and cleaning of the blade housing, in addition to monitoring the air compressor system, will assist identify the purpose. Replacing worn blades with the best specification is also critical for stopping incomplete cuts.

5. Software Communication Errors

Because RazorGage systems rely closely on software integration, verbal exchange errors between the laptop interface and the noticed hardware are some other common difficulties. These errors generally give themselves as delayed responses, command disasters, or frozen interfaces. They can be resulting from previous firmware, community interruptions, or USB connection problems. Keeping software up-to-date and verifying conversation ports in the system settings can solve many of these troubles. If using cloud-based programming in 2025, verifying firewall permissions and network configurations becomes an increasing number of essential for consistent communique.

6. Material Feeding Problems

A much less obvious but nonetheless impactful difficulty is inconsistent material feeding. If the inventory cloth doesn’t feed easily into the slicing location, it could result in misaligned cuts or even mechanical pressure on the machine. Feeding troubles regularly stand up from worn rollers, misaligned guides, or lubrication issues. In automatic settings, sensors stumble on and regulate cloth function, but if sensors are misaligned or grimy, they will provide false readings. Regular cleaning and alignment of the feed components ensure smoother operations. Upgraded fashions in 2025 now consist of self-correcting feeders, however those nonetheless require user monitoring to feature correctly.

7. Pneumatic System Malfunctions

Since RazorGage Upcut Saws depend heavily on pneumatic actuation for blade movement, any problems inside the air machine can halt operations. Air pressure inconsistencies, hose leaks, or valve clogs are common culprits. If the saw blade fails to upward thrust or appears slow, it’s smart to check the stress gauge and look into for audible air leaks. Filters, regulators, and lubricators inside the air delivery device must be maintained often. In 2025, many systems provide virtual strain video display units that can give early warnings earlier than failure happens. Monitoring those indicators is essential for minimizing unplanned downtime.

8. Safety Sensor Interference

Safety is a top priority in current reducing structures, and the RazorGage Upcut Saw includes a couple of protection sensors and interlocks. If the gadget refuses to perform or all of sudden stops mid-cycle, the purpose may be interference or misalignment inside the safety sensors. Common scenarios include dust buildup, unintentional blockage, or wiring faults. Some saws are programmed to prevent while any sensor is precipitated or loses connection. A thorough inspection of light curtains, door switches, and emergency stops can pinpoint the difficulty. In 2025, a few more recent models function wi-fi safety structures, which require additional configuration steps for the duration of troubleshooting.

9. Overheating and Motor Failures

Extended operation or bad air flow can cause overheating of cars and other electrical components. Overheating causes performance degradation and may sooner or later harm inner elements. If the RazorGage Upcut Saw appears slower than regular or stops suddenly, thermal overload protection could be attractive. Ensuring that the gadget has adequate airflow and that every one cooling fans are functioning properly is prime. Motor bearings need to also be inspected for put on, mainly in excessive-usage environments. With smarter sensors in 2025, the machine may alert customers to temperature spikes, allowing preemptive intervention earlier than primary failure occurs.

10. Maintenance Gaps and Preventive Measures

Most RazorGage Upcut Saw issues stem from abnormal or insufficient preservation workouts. Even with advanced diagnostics and automation in 2025, these machines require human oversight to stay in height condition. Lubrication schedules, blade replacement periods, sensor cleaning, and software exams ought to all be followed diligently. Lack of training or oversight in upkeep can result in cumulative put on that subsequently consequences in bigger failures. Manufacturers regularly provide upkeep logs and alert structures in cutting-edge saws, and it’s vital to apply them. Documenting any irregular behavior and preserving an up-to-date provider history helps technicians pick out patterns and address problems greater successfully.

Conclusion

In 2025, troubleshooting not unusual RazorGage Upcut Saw troubles requires a blend of mechanical expertise, software literacy, and attention to element. From power troubles to sensor misalignment and pneumatic failure, know-how the foundation causes of every issue allows operators to reply successfully and prevent long-term harm. As systems turn out to be extra superior, staying proactive is vital in optimizing saws for better performance and much less downtime. Leveraging those insights ensures clean operations, specifically while dealing with complicated materials or huge-scale slicing obligations. For those seeking to extend the life and performance in their RazorGage Upcut Saw, maintaining disciplined troubleshooting and maintenance recurring remains the most reliable approach.