Top Solutions to Most Common PCB Assembly Challenges

The assembly of a printed circuit board (PCB) is pivotal in electronics manufacturing. PCBs are the backbone of most electronic...

The assembly of a printed circuit board (PCB) is pivotal in electronics manufacturing. PCBs are the backbone of most electronic devices, and the assembly process determines their functionality and reliability. Star Engineering, Inc. offers custom PCB assembly services that epitomize excellence and innovation in this sector. This blog explores the common challenges faced during PCB assemblies, provides practical solutions, and more.

Understanding PCB Assembly

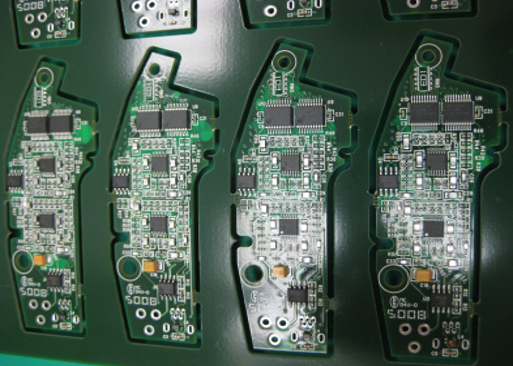

Custom PCB assembly involves the meticulous process of mounting electronic components onto a PCB. A PCB is a canvas for assembling various elements, such as capacitors, resistors, and integrated circuits, which are surface-mounted or inserted through holes. Star Engineering, Inc. specializes in both types of assemblies, ensuring versatility and precision for every client’s unique needs.

Common PCB Challenges and Solutions

Here are some common challenges and solutions for PCB assemblies:

Component Sourcing Challenges

Procuring specific components on time and within budget can be a significant obstacle. This is often due to:

- Global supply chain disruptions: Shortages and delays are becoming increasingly common, impacting component availability.

- Obsolescence: Components can become obsolete quickly, requiring alternative solutions.

- Minimum order quantities (MOQs): Distributors may impose high MOQs, which can lead to excess inventory for smaller projects.

Solutions:

- Partnering with reliable distributors: It is crucial to build relationships with reputable distributors who maintain diverse inventories and offer flexible ordering options.

- Utilizing alternative components: Working with clients to identify suitable alternative components that meet performance and budget requirements can mitigate the impact of shortages.

- Implementing lead time management strategies: Forecasting component needs, placing orders early, and actively monitoring lead times are essential for proactive planning.

Soldering and Assembly Defects

Even the most meticulous PCB design can be compromised by soldering and assembly defects. These can include:

- Solder bridges: Short circuits formed by excess solder connecting unintended points.

- Tombstoning: Components standing upright due to uneven solder application.

- Poor solder joints: Weak connections that can lead to electrical failures.

- Component misalignment: Incorrect placement of components on the PCB.

Solutions:

- Implementing robust quality control processes: Establishing thorough inspection procedures throughout the assembly process helps identify and rectify defects early.

- Utilizing advanced inspection equipment: Employing X-ray, automated optical inspection (AOI), and other advanced tools ensures precise component placement and solder quality.

- Employing skilled technicians: Investing in training and development ensures they possess the expertise and dexterity necessary for high-quality assembly.

Meeting Tight Deadlines

The pressure to deliver PCB assemblies on time is immense. Delays can have significant consequences, impacting production schedules and customer satisfaction.

Solutions:

- Streamlining the production process: Optimizing workflow by eliminating unnecessary steps and bottlenecks can significantly reduce assembly time.

- Utilizing efficient project management tools: Implementing software solutions that track progress, manage resources, and identify potential roadblocks enables proactive planning and timely delivery.

- Offering quick-turn PCB assembly services: Star Engineering Inc. understands the urgency of specific projects and offers custom circuit board assembly services to meet tight deadlines.

Budgetary Constraints

Balancing cost with quality is a constant challenge in PCB assembly. Clients often seek solutions that meet their budget without compromising functionality.

Solutions:

- Optimizing material selection: Utilizing cost-effective components that meet performance specifications can significantly reduce assembly costs.

- Implementing cost-saving measures without compromising quality: Employing techniques like value engineering and exploring alternative manufacturing processes can save costs without sacrificing quality.

- Exploring volume discounts with suppliers: Negotiating bulk purchase agreements with reliable suppliers can secure significant price reductions.

Design and Functionality Issues

PCB design flaws and functionality issues can lead to costly rework and delays.

Solutions:

- Collaborating closely with clients during the design phase: Active communication and feedback exchange throughout the design process ensures the final PCB aligns with client specifications and avoids potential functionality issues.

- Utilizing design for manufacturability (DFM) principles: Implementing DFM principles during the design phase ensures the PCB is optimized for efficient and high-quality assembly.

- Offering design review and optimization services: Star Engineering Inc. provides comprehensive design review and optimization for custom quick-turn PCB assembly to identify and rectify potential design flaws before assembly begins.

Staying Ahead of Technological Advancements

The PCB assembly industry is constantly evolving, with new technologies emerging rapidly.

Solutions:

- Investing in training and development for technicians: Providing ongoing training ensures technicians possess the skills and knowledge to handle the latest technologies and equipment.

- Implementing new technologies like surface mount technology (SMT): Embracing advanced technologies like SMT can enhance assembly efficiency and precision.

- Staying updated on industry trends and innovations: Actively monitoring industry trends and advancements allow Star Engineering Inc. to remain at the forefront of PCB assembly technology.

Overcoming PCB assembly challenges requires expertise, proactive planning, and a commitment to quality. Star Engineering Inc. has the experience, resources, and dedication to deliver high-quality PCB assemblies on time and within budget. We collaborate closely with our clients to understand their specific needs and implement effective solutions to ensure the success of their projects.

Partnering with Star Engineering, Inc.

Choosing Star Engineering as your PCB assembly partner comes with numerous advantages:

- Expertise and Versatility: Star Engineering, Inc. caters to a broad spectrum of industries, specializing in SMT and through-hole PCB assemblies.

- Rapid and Reliable: We are known for our fast response times and strive to maintain high-quality standards despite tight deadlines.

- Comprehensive Support: From design to final testing, comprehensive support ensures that every aspect of the PCB assembly meets the client’s specifications and industry standards.

Star Engineering, Inc., one of the leading electronic assembly companies, offers quality and reliability in the PCB assembly industry, adeptly navigating the challenges of modern electronic product demands. Whether you require a quick-turn solution or a complex, custom assembly, partnering with us ensures your projects are executed precisely and efficiently.