The Importance of Conveyor Pulley Lagging in Modern Industries

In the fast-paced world of industrial manufacturing, efficiency and reliability are paramount. Conveyor systems play a critical role in ensuring...

In the fast-paced world of industrial manufacturing, efficiency and reliability are paramount. Conveyor systems play a critical role in ensuring the seamless movement of materials across production lines. However, the performance of these systems heavily relies on their components, one of which is often overlooked but absolutely essential: conveyor pulley lagging. At Oliver Rubber LLP, we take pride in being one of the foremost manufacturers of high-quality rubber sheets in India, and our expertise extends to providing top-tier solutions for pulley lagging that enhance conveyor belt performance and longevity.

What is Conveyor Pulley Lagging?

Conveyor pulley lagging refers to the process of applying a protective layer, typically made of rubber or ceramic, to the surface of conveyor pulleys. These pulleys are the driving force behind conveyor belts, and their efficiency directly impacts the overall system. The lagging serves multiple purposes: it increases friction between the pulley and the belt, prevents slippage, protects the pulley from wear and tear, and extends the lifespan of both the pulley and the conveyor belt. Without proper lagging, industries risk downtime, reduced productivity, and costly repairs.

At Oliver Rubber LLP, we understand the critical role that conveyor pulley lagging plays in keeping manufacturing units running smoothly. Our commitment to excellence and innovation has made us a trusted name in the industry, and our pulley lagging sheets are designed to meet the diverse needs of our clients across sectors like automotive, construction, and heavy industry.

Why Pulley Lagging Matters

Conveyor belts are the backbone of material handling systems, transporting everything from raw materials to finished products. However, factors like wet or slippery conditions, heavy loads, and constant friction can cause belts to slip, leading to inefficiencies and potential damage. This is where pulley lagging comes into play. By enhancing the grip between the pulley and the belt, lagging ensures consistent performance even under challenging conditions.

Moreover, conveyor pulley lagging acts as a protective barrier. Pulleys are exposed to abrasive materials, moisture, and extreme temperatures, all of which can cause corrosion or degradation over time. Our high-quality lagging sheets at Oliver Rubber LLP shield the pulley surface, reducing maintenance costs and minimizing the need for frequent replacements. This not only saves money but also keeps production lines operational for longer periods.

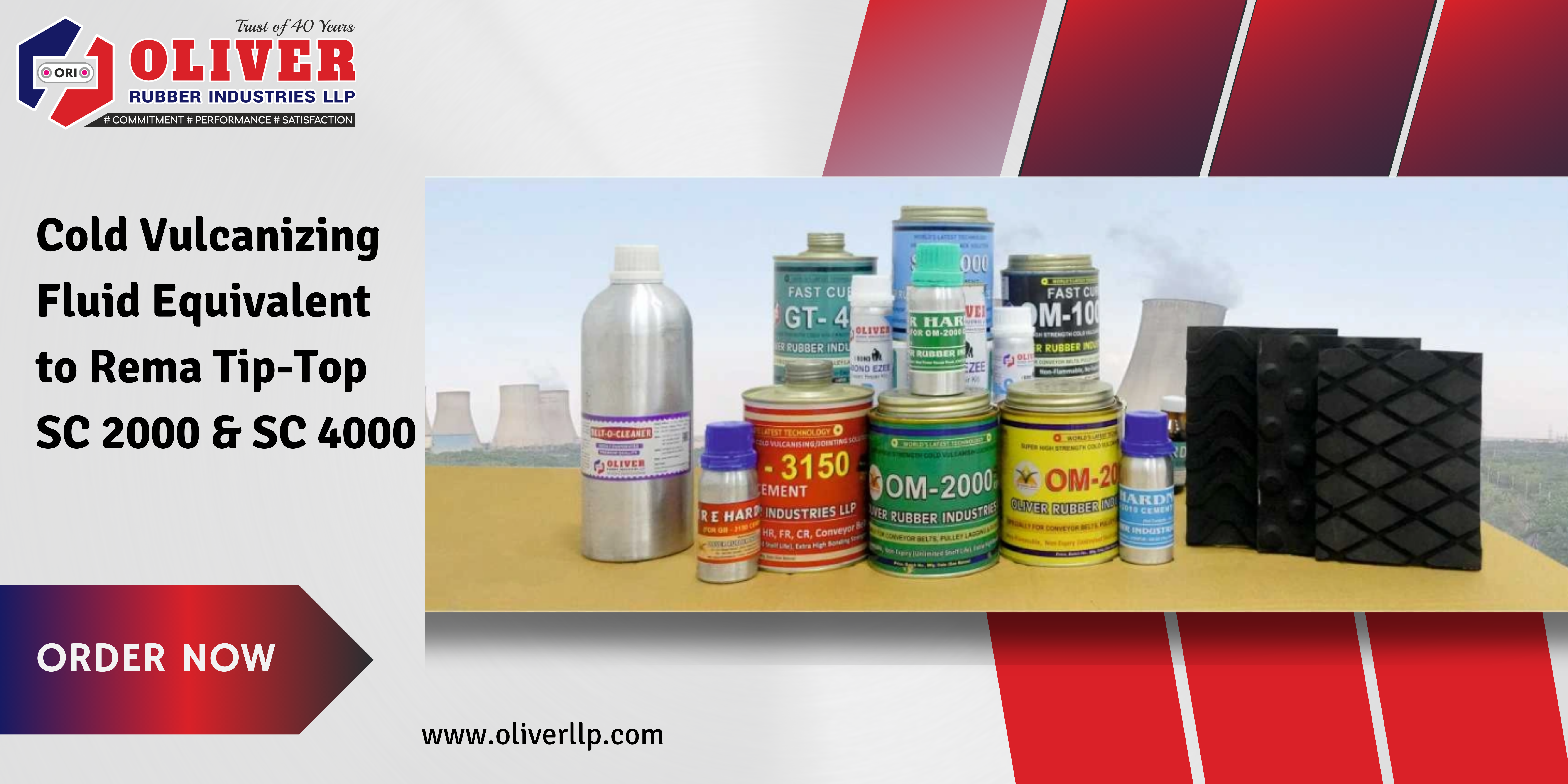

Our Solution: Pulley Lagging Sheets with Adhesive Cold Vulcanizing

At Oliver Rubber LLP, we know how important it is for conveyor belts to run smoothly in your manufacturing units. That’s why we provide the best pulley lagging sheets with adhesive cold vulcanizing technology. This advanced method ensures a strong bond between the lagging material and the pulley without the need for heat, making it a cost-effective and efficient solution for industries.

Our pulley lagging sheets are engineered to prevent belt slippage, a common issue that can disrupt operations and lead to material spillage or equipment damage. By increasing traction, our products ensure that the conveyor belt moves in sync with the pulley, even under high tension or heavy loads. Additionally, our lagging solutions are designed to extend the life of the conveyor belt, offering a durable layer that withstands wear and tear over prolonged use.

Customizable Solutions for Every Industry

One of the key strengths of Oliver Rubber LLP is our ability to cater to the unique requirements of every customer. We recognize that no two industries—or even two conveyor systems—are exactly alike. That’s why we offer customizable conveyor pulley lagging solutions tailored to your specific needs. Whether you require a particular thickness, hardness, or dimension, our team works closely with you to deliver a product that fits seamlessly into your operations.

Our extensive range of rubber sheets, including those used for pulley lagging, is manufactured using cutting-edge technology and the highest quality materials. This ensures that our products meet stringent industry standards while delivering exceptional performance. From small-scale workshops to large industrial plants, our lagging sheets provide the reliability and durability that businesses need to stay competitive.

Benefits of Choosing Oliver Rubber LLP for Pulley Lagging

When you partner with Oliver Rubber LLP, you’re choosing a company that prioritizes quality, innovation, and customer satisfaction. Here are some of the standout benefits of our conveyor pulley lagging solutions:

- Enhanced Traction: Our lagging sheets eliminate belt slippage, ensuring smooth and efficient conveyor operation.

- Durability: Made from premium rubber, our products resist abrasion, corrosion, and environmental damage, prolonging the life of your equipment.

- Cost Savings: By reducing wear on pulleys and belts, our lagging solutions lower maintenance and replacement costs.

- Easy Installation: The adhesive cold vulcanizing process simplifies application, minimizing downtime during installation.

- Versatility: With customizable options, our lagging sheets are suitable for a wide range of industries and conveyor systems.

Applications Across Industries

The versatility of conveyor pulley lagging makes it indispensable across various sectors. In the mining industry, for example, where conveyor belts transport heavy and abrasive materials like coal or ore, our lagging sheets provide the durability needed to withstand harsh conditions. In the automotive sector, they ensure precise movement of components along assembly lines. Construction sites benefit from the enhanced traction and longevity that our products offer, while food processing plants rely on our high-quality materials to meet hygiene and safety standards.

Why Oliver Rubber LLP Stands Out

With years of experience and a dedication to excellence, Oliver Rubber LLP has established itself as a leader in the rubber manufacturing industry in India. Our focus on research and development allows us to continually improve our products, ensuring that our pulley lagging solutions remain at the forefront of innovation. We combine state-of-the-art manufacturing processes with a customer-centric approach, delivering products that not only meet but exceed expectations.

Our team of experts is always ready to assist you in selecting the right conveyor pulley lagging for your specific application. Whether you’re looking to upgrade an existing system or install a new one, we provide the technical support and high-quality materials you need to succeed.

Conclusion

In conclusion, conveyor pulley lagging is a small yet vital component that can make a big difference in the performance and longevity of your conveyor system. At Oliver Rubber LLP, we take pride in offering top-notch pulley lagging sheets that prevent belt slippage, protect your equipment, and keep your operations running smoothly. With our customizable solutions and commitment to quality, we’re here to help you achieve maximum efficiency in your manufacturing units. Trust Oliver Rubber LLP to be your partner in success—because when it comes to conveyor performance, every detail counts.