The Impact of Automation Technology on theFuture of Manufacturing and Lifestyle

The manufacturing industry never stops as it is one of the most stable fields. It is also a conventional industry...

The manufacturing industry never stops as it is one of the most stable fields. It is also a conventional industry that is not known for its innovation. But, this is changing rapidly as several technological advancements are constantly revolutionising the manufacturing landscape. One of these major advancements is the introduction of smart automation technology.

The surge in technological advancements in the manufacturing industry is resulting in the most exciting developments in the sector. Industries are accelerating their operations with the adoption of cutting-edge technologies like AI, industrial automation and robotics. But what are these automations, and how are they changing the future of the manufacturing industry? Curious to know? Continue reading this comprehensive article by the Schunk team. It provides detailed insight into the future of the manufacturing industry due to the increasing use of automation technology.

What is Automation in the Manufacturing Industry?

The integration of an industrial automation system in the production processes of goods refers to automation in the manufacturing industry. It involves the integration of automation systems and robotics in machinery and other production lines to speed up the process and reduce human work. Automation allows human operators in industrial units to automate tasks and reduce their labour. The automation systems primarily work to enhance the efficiency of production processes and the quality of the products.

Ways Automation is Revolutionising the Manufacturing Industry

By using the following ways, the automation industry in India is revolutionising the manufacturing industry.

Automated Workflows

The digital infrastructure of the manufacturing world is changing rapidly. It is constantly retooling to support more sourcing and reporting activities and agile product development activities. But what is the need for this retooling? The changing customer demands, supply shortages and regulations are some of the main reasons for this. Automation systems can help integrate external data, connect data silos and provide automated decision workflows. These systems do so by reducing costs, accelerating development and mitigating risks.

Quality Enhancement

Another way industrial automation and robotics are helping and will help in the future is by converting dreams and visions into reality. These systems significantly help manufacturing teams to produce high-quality goods by minimising errors in the process. For example, AI can detect wrinkles during car seat assembly and prevent them timely.

Automation of Repetitive Tasks

Production lines have several repetitive tasks. Traditionally, human operators in the units had to perform repetitive tasks. However, the automation industry in India is helping to automate these tasks. Robots and machines take care of these tasks, increasing production and reducing errors. These smart machines can be instructed to automate any desired tasks in the production lines.

Machine Monitoring

Machines are the most crucial part of the modern industrial units. The breakdown of even a single machine can disrupt the entire production process. An industrial automation system can prevent such downtime situations. Various AI tools can be used in manufacturing units. These tools send automated alerts for regular maintenance of the machines to prevent their breakdown and costly repairs.

Enhances Productivity

Manufacturing industries shifted from manual work to machines. However, the increasing demand of customers requires these machines to enhance their productivity, which will result in better overall productivity. Automation helps with this. The automation systems and robotics enhance the cost efficiency, production speed and quality. Therefore, these systems completely optimise the manufacturing processes for better productivity.

Makes Workplace Safe

Manufacturing units pose numerous threats to workers. These threats can result in severe accidents. However, the integration of robotics and automation makes them a safer workplace. The beauty of automation lies in eliminating monotonous or dangerous human labour. Advanced robots and automation systems collectively work to perform dangerous tasks on their own and prevent human operators from operational risks.

Standardised Processes

Smart automation technology is leaving a stabilising effect on the manufacturing industry. It provides data-driven insights to the human operators related to the production lines. This data helps with decision-making regarding standardising manufacturing processes. Using these automated data, operators can predict production times. It also helps gain deeper insights into every stage of production and reduce inefficiencies.

Automation Trends in the Manufacturing Industry

Some of the most significantly emerging automation trends in the manufacturing industry involve the following.

Increased Use of Interconnected Robots

Today, traditional human labour and conventional robots are being replaced by Co-Bots. These advanced robots work alongside their human counterparts. Collaborative robots are easy to operate, and they perform their part of the work independently. However, they are capable of human interaction, and even a non-robotics expert can change their system and ask them to work on a different task. They are versatile and easy to use.

Industry 4.0 for Automation

Industry 4.0 refers to the fourth industrial revolution. Automation in the manufacturing industry is swiftly adopting this revolution. It involves the integration of artificial intelligence, robotics, advanced technologies and the Internet of Things (IoT). The integration of these technologies makes traditional factories smart by enhancing their productivity.

In the End

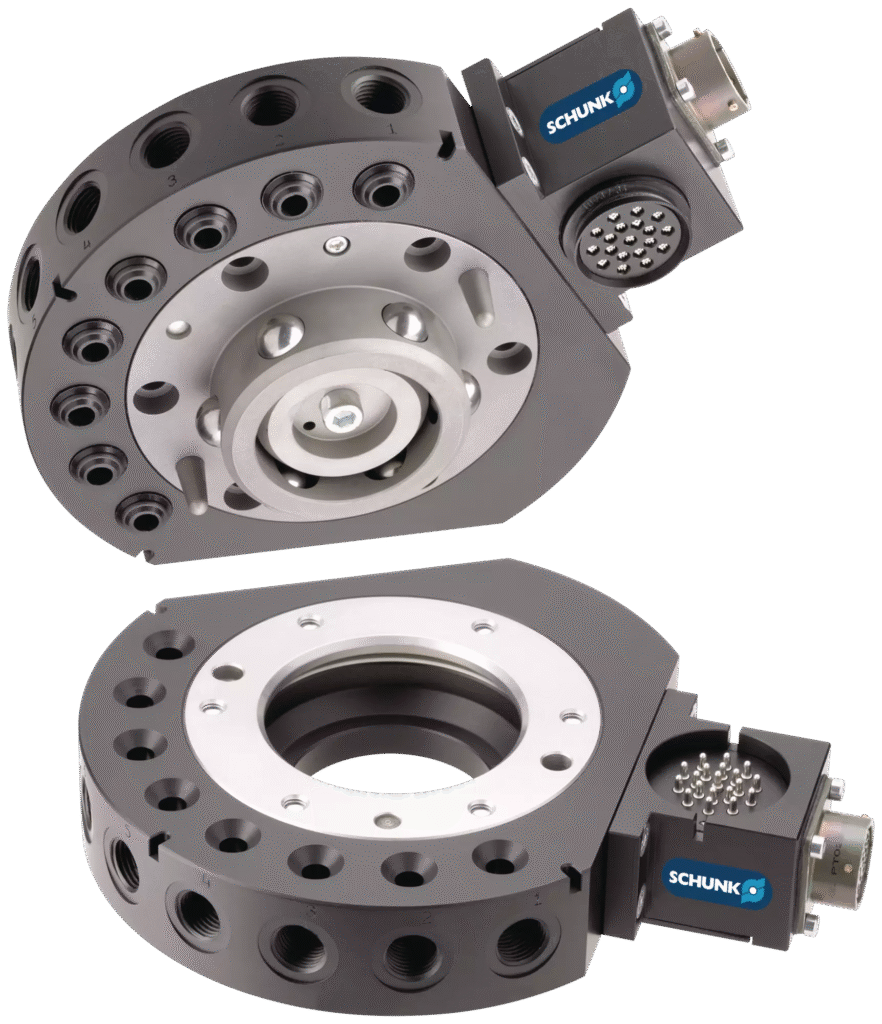

Automation is revolutionising almost every field. The manufacturing industry is no exception. It is constantly bringing changes in the production processes. Schunk is a major contributor to this revolution and is a significant part of the automation industry in India. We offer the best robotics parts, such as robotic arms and sensors, for manufacturing units. Our high-quality products are helping hundreds of manufacturing units to enhance their overall efficiency.

Frequently Asked Questions

What is the impact of automation on the manufacturing industry?

Automation is significantly helping the manufacturing industry to enhance its productivity. The automation systems enhance the production speed. They also make manufacturing units a safer place for human workers by reducing operational hazards.

What is the future of automation in the manufacturing industry?

The future of automation in the manufacturing industry is rather bright. More and more manufacturing industries are shifting towards the integration of robotics and automation in their production lines. One of the most significant trends that will rise is the use of collaborative robots.