Self-Cleaning Filters Market Outlook (2025–2033): Trends, Growth Drivers, and Future Prospects

Introduction As industries around the world strive for greater efficiency, automation, and sustainability, the demand for self-cleaning filters has surged...

Introduction

As industries around the world strive for greater efficiency, automation, and sustainability, the demand for self-cleaning filters has surged significantly. These filters, designed to eliminate the need for manual cleaning, are increasingly being integrated into industrial systems to improve productivity, reduce downtime, and lower operational costs. Whether in water treatment facilities, the food and beverage industry, or petrochemical plants, self-cleaning filters offer a robust solution to filtration challenges in demanding environments.

This article presents a detailed analysis of the global self-cleaning filters market from 2025 to 2033. It explores key growth drivers, emerging trends, market segmentation, regional dynamics, challenges, and future prospects shaping the industry landscape.

Market Overview

Current Market Size and Forecast

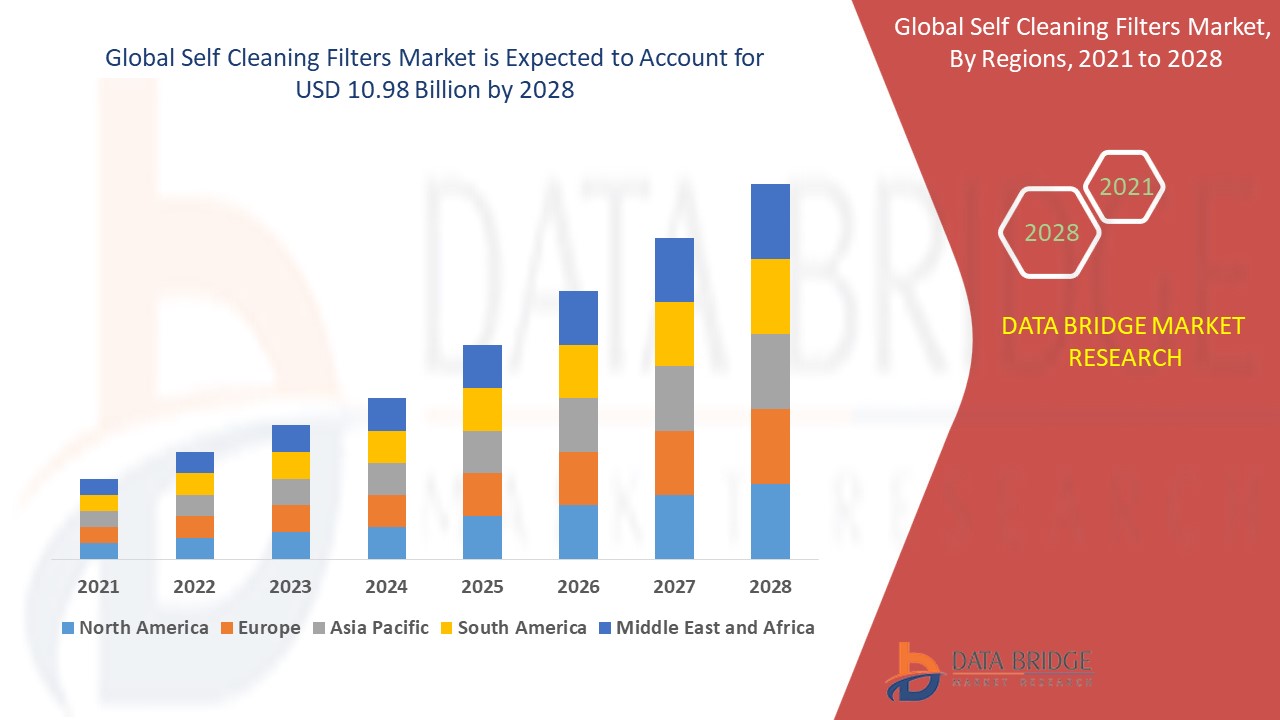

In recent years, the self-cleaning filters market has witnessed consistent growth due to rapid industrialization, increasing automation, and stricter environmental regulations. As of 2024, the market was valued at approximately USD 6.7 billion. Forecasts indicate that the market will reach approximately USD 11.5 billion by 2033, growing at a compound annual growth rate (CAGR) of 6.5% to 7.5% during the forecast period.

The adoption of self-cleaning filters is expanding beyond traditional sectors like water treatment and oil and gas to include pharmaceuticals, food and beverage processing, agriculture, and even aquaculture.

Key Market Drivers

1. Growing Emphasis on Operational Efficiency

One of the primary drivers of market growth is the increasing demand for automated and maintenance-free filtration solutions. Self-cleaning filters operate continuously without halting the system, thereby improving uptime, reducing labor costs, and minimizing the need for frequent manual intervention.

2. Stringent Environmental Regulations

Governments and environmental bodies worldwide are enforcing stricter regulations related to water discharge, emissions, and waste management. Industries must comply with these regulations, and self-cleaning filters offer an efficient way to meet environmental standards by removing solid particles and contaminants effectively.

3. Rising Water Scarcity and Demand for Reuse

Water scarcity is an escalating global issue. Industries are now focusing on water reuse and recycling, which requires high-performance filtration systems. Self-cleaning filters help remove suspended solids from wastewater, enabling reuse for industrial operations or safe discharge, thereby contributing to water conservation efforts.

4. Expansion of Process Industries

The growth of industries such as food and beverage, pharmaceuticals, and chemicals has spurred the demand for reliable filtration systems. These sectors require a high level of hygiene and continuous operation, both of which are facilitated by self-cleaning filters.

Market Segmentation

By Filter Type

Backwash Filters

Backwash filters are widely used for applications involving high contaminant loads. They function by reversing the flow of liquid to remove the accumulated solids. These filters are ideal for water treatment and industrial cooling systems.

Scraper Filters

Scraper filters use mechanical scrapers to remove debris from the filter surface. They are particularly effective in handling viscous liquids and slurries, often found in food processing and pulp and paper industries.

Suction Scanning Filters

These filters employ suction nozzles to clean the filter element. They are suitable for fine filtration applications and are popular in agricultural and irrigation systems.

Brush Filters

Brush filters utilize rotating brushes to clean the filtration screen. These are suitable for low to medium flow applications and are often found in HVAC systems and municipal water supplies.

By Material

- Stainless Steel: Preferred for its durability, resistance to corrosion, and suitability for high-pressure environments.

- Plastic/Polymer: Lightweight and cost-effective, suitable for less demanding applications and clean water systems.

By Flow Rate

- Low Flow (<100 m³/h)

- Medium Flow (100–500 m³/h)

- High Flow (>500 m³/h)

The selection of a filter based on flow rate depends on the scale of the operation and the nature of the application.

By End-Use Industry

- Water and Wastewater Treatment

- Oil and Gas

- Food and Beverage

- Chemical and Petrochemical

- Pharmaceuticals

- Agriculture and Irrigation

- Power Generation

Regional Analysis

North America

North America remains a key market for self-cleaning filters due to the region’s strong industrial base, high awareness of sustainable practices, and robust environmental regulations. The United States, in particular, sees widespread adoption across sectors like water treatment and petrochemicals.

Europe

European countries are heavily investing in environmentally sustainable solutions. The EU’s strict waste and water discharge norms drive demand for self-cleaning filters. Germany, France, and the UK are prominent contributors to market growth in the region.

Asia-Pacific

Asia-Pacific is expected to witness the fastest growth during the forecast period. Rapid industrialization in countries like China, India, and Indonesia, coupled with increasing investment in water infrastructure, is propelling the demand. Moreover, governments in the region are pushing for better wastewater management systems.

Latin America and Middle East & Africa

These regions are gradually adopting advanced filtration technologies, mainly in water-scarce areas. The growth is supported by infrastructure projects, increasing awareness, and international funding for water conservation and treatment.

Emerging Trends

Integration with Smart Technologies

The integration of self-cleaning filters with IoT and automation systems enables real-time monitoring, predictive maintenance, and data analytics. This not only ensures system reliability but also provides insights for improving operational efficiency.

Energy-Efficient Systems

Manufacturers are focusing on reducing the energy consumption of filtration systems. Low-energy motors, optimized backwash cycles, and pressure-based actuation mechanisms are becoming standard.

Customized Solutions for Niche Applications

Industry-specific filtration requirements are leading to the development of customized filter solutions. For example, food-grade stainless steel filters for dairy applications or anti-clogging filters for irrigation systems.

Challenges

High Initial Cost

Despite long-term savings, the upfront investment required for installing self-cleaning filters is relatively high compared to conventional filters. This can deter small and medium-sized enterprises from adopting them.

Technical Complexity

The design and operation of self-cleaning filters can be technically complex. Proper training and skilled personnel are required for installation, operation, and troubleshooting.

Competition from Traditional Filtration Systems

In regions where automation and technological advancement are slower, conventional filtration systems continue to dominate due to their lower cost and simpler operation.

Competitive Landscape

The self-cleaning filters market is moderately fragmented, with the presence of several global and regional players. Key strategies include:

- Product Innovation: Companies are focusing on enhancing filter performance through advanced materials and automation.

- Strategic Partnerships: Collaborations with system integrators, EPC contractors, and water treatment firms.

- Geographical Expansion: Targeting emerging markets in Asia and Africa to increase market penetration.

Some of the leading manufacturers in this space include companies specializing in water technology, industrial filtration, and process automation equipment. They offer a diverse portfolio of filters suited to a wide range of industrial and municipal applications.

Future Outlook (2025–2033)

Looking ahead, the self-cleaning filters market is expected to evolve significantly due to the following factors:

- Rising Demand for Water Reuse: Accelerated efforts toward sustainability will push industries to adopt more efficient and automated filtration systems.

- Adoption of Industry 4.0: As industries digitize, the role of smart filters will become central in managing system integrity and operational efficiency.

- Growth in Infrastructure Development: Investment in wastewater treatment plants, irrigation systems, and smart cities will increase demand.

- Environmental Sustainability: Stricter emissions and waste control measures will drive industries to choose efficient and eco-friendly technologies.

By 2033, the market is anticipated to not only expand in terms of value but also become more technologically advanced and environmentally aligned.

Source: https://www.databridgemarketresearch.com/reports/global-self-cleaning-filters-market

Conclusion

The self-cleaning filters market stands at a pivotal juncture in its growth trajectory. As industries prioritize automation, efficiency, and sustainability, these filtration systems offer a compelling solution that meets multiple operational and regulatory needs. While high initial costs and technical complexity present challenges, the long-term benefits in terms of reduced maintenance, improved uptime, and environmental compliance make self-cleaning filters a smart investment.

With advancements in smart technologies, rising water management concerns, and the global shift toward sustainable industrial practices, the future of the self-cleaning filters market looks promising. Stakeholders who invest in innovation, customization, and smart integration will be well-positioned to thrive in this evolving landscape.