Roofing Machines: The Essential Equipment Every Roofer Needs

Roofing is one of the most demanding tasks in the construction industry. Whether you are installing a new roof or...

Roofing is one of the most demanding tasks in the construction industry. Whether you are installing a new roof or performing maintenance on an existing one, the right tools can make a significant difference in efficiency, quality, and safety. Roofing machines have evolved to meet the needs of modern contractors, streamlining tasks that once took days into hours. For professional roofers and serious DIYers, understanding the essential equipment is key to achieving durable and high-quality results.

Why Roofing Machines Matter

Roofing machines are more than just luxury tools—they are vital for speeding up installation, reducing labor costs, and minimizing errors. Traditional roofing methods rely heavily on manual labor, which is time-consuming and physically demanding. By incorporating roofing machines into the workflow, professionals can cut installation time dramatically while maintaining precision and safety.

Not only do these machines enhance productivity, but they also ensure that roofing materials are installed correctly. Proper installation is critical because even minor mistakes can lead to leaks, structural damage, or premature wear.

Types of Roofing Machines

There are several types of roofing machines, each designed to handle a specific task. Understanding these machines can help contractors select the right equipment for their projects.

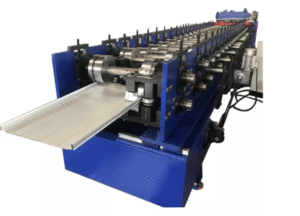

1. Roll Forming Machines

Roll forming machines are primarily used for creating metal roofing panels. These machines take flat sheets of metal and shape them into panels with specific profiles, such as standing seam or corrugated designs. Roll forming machines are essential for contractors who want consistent quality and efficiency in producing custom metal panels on-site.

2. Shingle Cutters and Nailers

For asphalt shingles, specialized machines like shingle cutters and pneumatic nailers make the process faster and more precise. Shingle cutters ensure uniform cuts for edges and corners, while nailers secure shingles quickly and consistently. These machines reduce the physical strain on workers and minimize mistakes that can lead to leaks or misalignment.

3. Seamers and Crimping Machines

Seamers and crimping machines are essential for metal roofing systems. These machines ensure tight seams between panels, preventing water infiltration. Proper seam alignment is critical for both aesthetic appeal and functional protection against the elements.

4. Gutter Machines

Though not directly part of the roofing surface, gutter machines are often included in roofing equipment sets. They allow contractors to create custom gutters that perfectly fit a roof’s dimensions. Properly installed gutters protect the building from water damage and extend the life of the roof.

5. Roof Cutting and Drilling Machines

For complex roofing projects, cutting and drilling machines provide precision for metal, wood, and composite materials. These machines ensure clean cuts and holes, reducing the risk of material damage and improving installation accuracy.

Benefits of Using Roofing Machines

The use of roofing machines provides several advantages for professionals and homeowners alike.

1. Increased Efficiency

One of the most significant benefits is efficiency. Tasks that previously required hours of manual labor can now be completed in a fraction of the time. For example, a roll forming machine can produce metal panels quickly and accurately, which reduces production delays and project timelines.

2. Consistent Quality

Machines deliver consistent results. When cutting shingles or forming metal panels, precision is critical. Roofing machines maintain uniformity across the entire roof, ensuring a professional finish that lasts longer and performs better.

3. Reduced Physical Strain

Roofing is physically demanding, often requiring workers to lift heavy materials, bend repeatedly, and work in challenging weather conditions. Roofing machines reduce the physical workload, minimizing fatigue and the risk of injury.

4. Cost Savings

While roofing machines represent an upfront investment, they save money in the long run. Faster installation means lower labor costs, fewer mistakes, and reduced material waste. Additionally, durable installations reduce the likelihood of repairs and maintenance costs over time.

Choosing the Right Roofing Machines

Selecting the right roofing machine depends on the type of roofing materials, the scale of the project, and the contractor’s experience. Here are some considerations:

- Project Type: Residential vs. commercial projects may require different machinery. Large commercial buildings benefit more from roll forming machines, whereas residential projects may rely heavily on shingle cutters and nailers.

- Material: The type of roofing material—metal, asphalt shingles, wood shakes—dictates which machines are necessary. Using the wrong equipment can lead to poor results.

- Mobility and Size: Some machines are portable and suitable for on-site production, while others are stationary and better for shop use. Evaluating mobility needs ensures smoother project execution.

- Budget: High-quality machines often come at a premium, but investing in reliable equipment reduces downtime, repair costs, and material waste. Choosing the right balance between cost and quality is essential.

Safety Considerations

Roofing is inherently risky, but the right machinery can improve safety. Many modern roofing machines come with safety features such as emergency stop buttons, protective guards, and automated operations that reduce manual handling. Proper training is critical, as misuse of machinery can lead to injuries or damage. Contractors should ensure that all workers are trained to operate machines correctly and follow safety protocols consistently.

Maintenance of Roofing Machines

To ensure longevity and optimal performance, roofing machines require regular maintenance. Cleaning, lubrication, and inspection of moving parts should be done routinely. Manufacturers typically provide detailed maintenance schedules and guidelines. Neglecting maintenance can result in machine breakdowns, delays, and costly repairs, so a proactive approach is always recommended.

Conclusion

Roofing machines have transformed the roofing industry, making it faster, safer, and more precise. From roll forming machines to shingle cutters, seamers, and gutter machines, the right equipment allows contractors to complete projects efficiently while ensuring high-quality results. Investing in these machines not only improves productivity but also enhances safety and long-term performance.