PLC Panels Explained: Why They Matter in Automation

If you work in automation or run a factory, you’ve likely heard of a PLC control panel. But knowing the...

If you work in automation or run a factory, you’ve likely heard of a PLC control panel. But knowing the name and knowing what it really does are two different things. Many people struggle to choose the right panel, or they get stuck with setups that break down, cost too much, or don’t fit their needs. That leads to wasted time, frustrated staff, and money down the drain.

This guide is here to clear things up. Whether you’re just getting started or picking a PLC panel manufacturer, we’ll break things down in a way that’s easy to follow. No jargon. No fluff. Just clear info on why PLC control panels matter and how they fit into your automation setup.

What Is a PLC Control Panel?

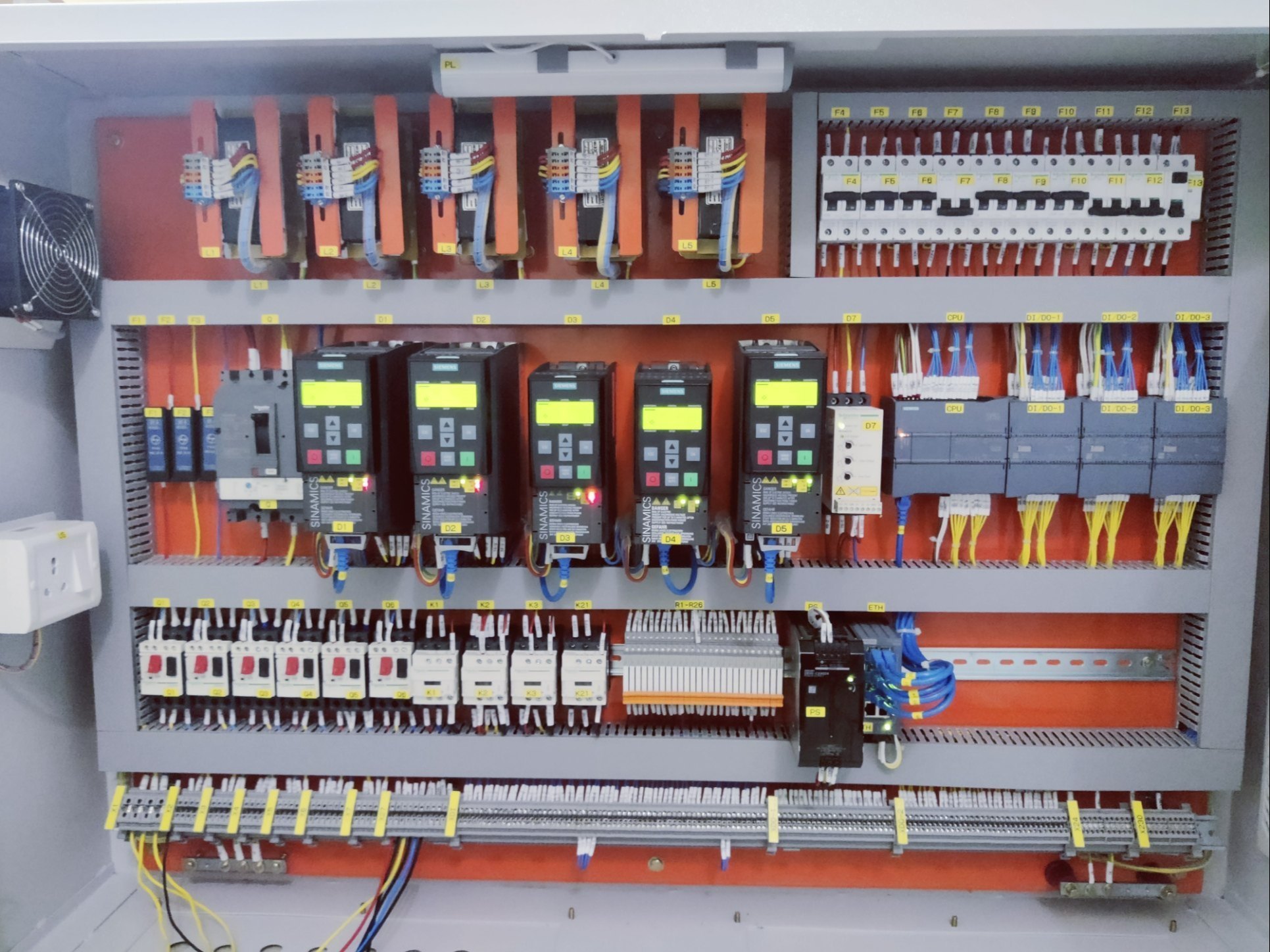

A PLC control panel is an electrical cabinet that houses a Programmable Logic Controller (PLC), which runs automation systems. Think of it as the brain that tells machines what to do and when to do it.

Here’s what a standard PLC panel includes:

- The PLC unit (main controller)

- Input and output (I/O) modules

- Circuit breakers and relays

- Power supply

- Terminal blocks and wiring

These parts work together to receive data from sensors and devices, process it using a program, and then send commands to other machines.

Use Case Example

A factory uses sensors to count how many bottles pass on a line. The PLC reads that data and tells a robot arm to box them after ten units. That’s a PLC in action—fast, exact, and repeatable.

Why PLC Panels Are the Backbone of Industrial Automation

You can’t run a modern automation setup without a reliable PLC control panel. Here’s why they’re used in almost every industry:

- Control speed and accuracy

A PLC sends commands in real time, which helps cut down on delays and errors. - Easy to change or update

Need to change how a system runs? Update the code inside the PLC—no need to swap out wires or rebuild the system. - Safe and smart

Panels come with circuit protection, reducing fire and shock risks. - Works with other systems

PLCs can link to SCADA, HMI, and sensors, allowing for full control and remote access.

Popular Industries Using PLC Panels

- Manufacturing

- Food processing

- Packaging

- Oil & gas

- Water treatment

Key Parts You’ll Find in a Quality PLC Panel

Let’s look at the most important parts inside a PLC control panel manufacturer setup. Each part plays a role in helping your automation system work without fail.

1. PLC Unit

This is the main controller. It runs the program and sends commands.

2. I/O Modules

Input modules take data from buttons or sensors. Output modules send signals to lights, motors, or valves.

3. Power Supply

Keeps everything running smoothly by giving stable power to the PLC and all components.

4. Relays and Contactors

These act like switches to start or stop motors based on what the PLC says.

5. Circuit Protection

Fuses and breakers protect against overloads or short circuits.

6. Terminal Blocks & Wiring

Used to connect sensors, relays, and other devices cleanly and safely.

How to Choose the Right PLC Panel Manufacturer

Choosing the right plc panel manufacturer can make or break your automation project. Here’s what to look for:

1. Experience with Industrial Projects

Pick someone who builds panels for your type of work—whether that’s packaging, chemical, or energy.

2. Custom Design Support

Every process is different. A good provider can build custom panels to match your needs.

3. Quality Control and Testing

Ask if they test panels before delivery. Bad wiring or loose parts cause problems later.

4. After-Sales Support

Good help doesn’t end after the sale. You want a team that can help when issues come up.

5. Compliance and Certifications

Make sure they follow safety and electrical codes like UL, CE, or IEC where required.

How PLC Panels Are Built: A Look Inside the Process

A strong automation setup starts with a well-built PLC control panel. Let’s break down how a panel is made, from start to finish.

1. Design Phase

Before anything gets built, engineers create a layout. This includes:

- The panel size

- The type of PLC used

- How many inputs and outputs are needed

- Electrical loads and safety limits

They also draw wiring diagrams, which act like blueprints for the build.

2. Component Selection

Each part is chosen based on the project’s needs. A top plc panel manufacturer picks parts from trusted brands to avoid failure or overload.

3. Assembly and Wiring

In this stage, the panel gets wired and assembled. Wires are labeled and routed neatly for easy maintenance. Good wiring is key to long-term performance.

4. Programming the PLC

The brain of the system gets loaded with a custom program. This controls when machines turn on, off, or adjust their speed.

5. Testing and Quality Checks

Before shipping, the panel goes through full testing. This includes:

- Power-up tests

- Load simulations

- Safety checks

Panels that pass are then packed and shipped for installation.

PLC Automation Panels vs Traditional Panels

Let’s compare PLC automation panels with older control setups that rely on relays or manual switches.

| Feature | Traditional Control Panel | PLC Control Panel |

|---|---|---|

| Flexibility | Hard to change | Easy to reprogram |

| Size | Bulky | Compact |

| Response Time | Slower | Fast and real-time |

| Maintenance | More manual work | Easier with software support |

| Expansion Options | Limited | Easy to scale |

In short, PLC control panels save time, space, and money in the long run.

Common Problems Solved by a Good PLC Control Panel

Many plants face similar issues with automation. The right PLC panel can solve most of them fast.

1. Machine Downtime

Problem: Machines stop for unknown reasons.

Fix: A PLC logs errors and keeps the system running or alerts staff right away.

2. Manual Errors

Problem: Operators press the wrong buttons or forget steps.

Fix: PLCs follow the same steps every time—no missed steps or skipped parts.

3. Inconsistent Production Rates

Problem: Different speeds from different shifts or staff.

Fix: PLCs run machines at one set speed. You get repeatable results every time.

4. High Energy Costs

Problem: Machines stay on longer than needed.

Fix: PLCs shut them off when not in use, cutting waste.

5. Trouble Finding Parts

Problem: Old panels use parts no longer made.

Fix: Modern PLC panels use standard components that are easy to find.

FAQs About PLC Control Panels

1. What is a PLC control panel?

A PLC control panel is an enclosure that houses a programmable logic controller and components to run machines automatically.

2. Who makes the best PLC control panels?

Top panel makers are those with industry experience, strong testing processes, and support for custom designs like PIMA Industrial.

3. Why are PLC panels used in automation?

They let machines work faster, safer, and with less human input by running preset programs.

4. How does a PLC control panel work?

It takes input from sensors, processes it using a program, then sends commands to devices like motors or lights.

5. Where are PLC panels used?

They’re used in factories, oil plants, water systems, food lines, and more.

6. Will a PLC panel save money?

Yes, by cutting down errors, saving energy, and reducing downtime.

7. How long does a PLC panel last?

With proper care, they can run 10–15 years or more.

8. What’s the difference between PLC and relay logic?

PLC logic is done by software, while relay logic uses hardwired switches.

9. Can PLC panels be upgraded?

Yes, they can be updated with new programs or parts as your process changes.

10. What should I ask a PLC panel manufacturer before buying?

Ask about their build quality, testing process, past projects, and support after delivery.

Conclusion: Smart Automation Starts With the Right PLC Control Panel

A PLC control panel is more than just a box of wires. It’s what keeps your automation running on time, every time. With smart design, solid parts, and the right plc control panel manufacturer, you’ll spend less time fixing problems and more time getting things done. If you’re building or upgrading a system, don’t cut corners. Work with experts like PIMA Industrial, who understand how to build panels that actually work in real-world settings.

Ready to build a smarter system?

Get in touch with our team today and see how we can support your automation needs—big or small.