How to Optimize a Packaged Sewage Treatment Plant with SCADA

In recent years, the integration of SCADA (Supervisory Control and Data Acquisition) systems in packaged sewage treatment plants has become...

In recent years, the integration of SCADA (Supervisory Control and Data Acquisition) systems in packaged sewage treatment plants has become a game-changer for wastewater management. For property owners and businesses looking to invest in these systems, understanding the role of SCADA can help make informed decisions about optimising their wastewater treatment processes.

What is a Packaged Sewage Treatment Plant?

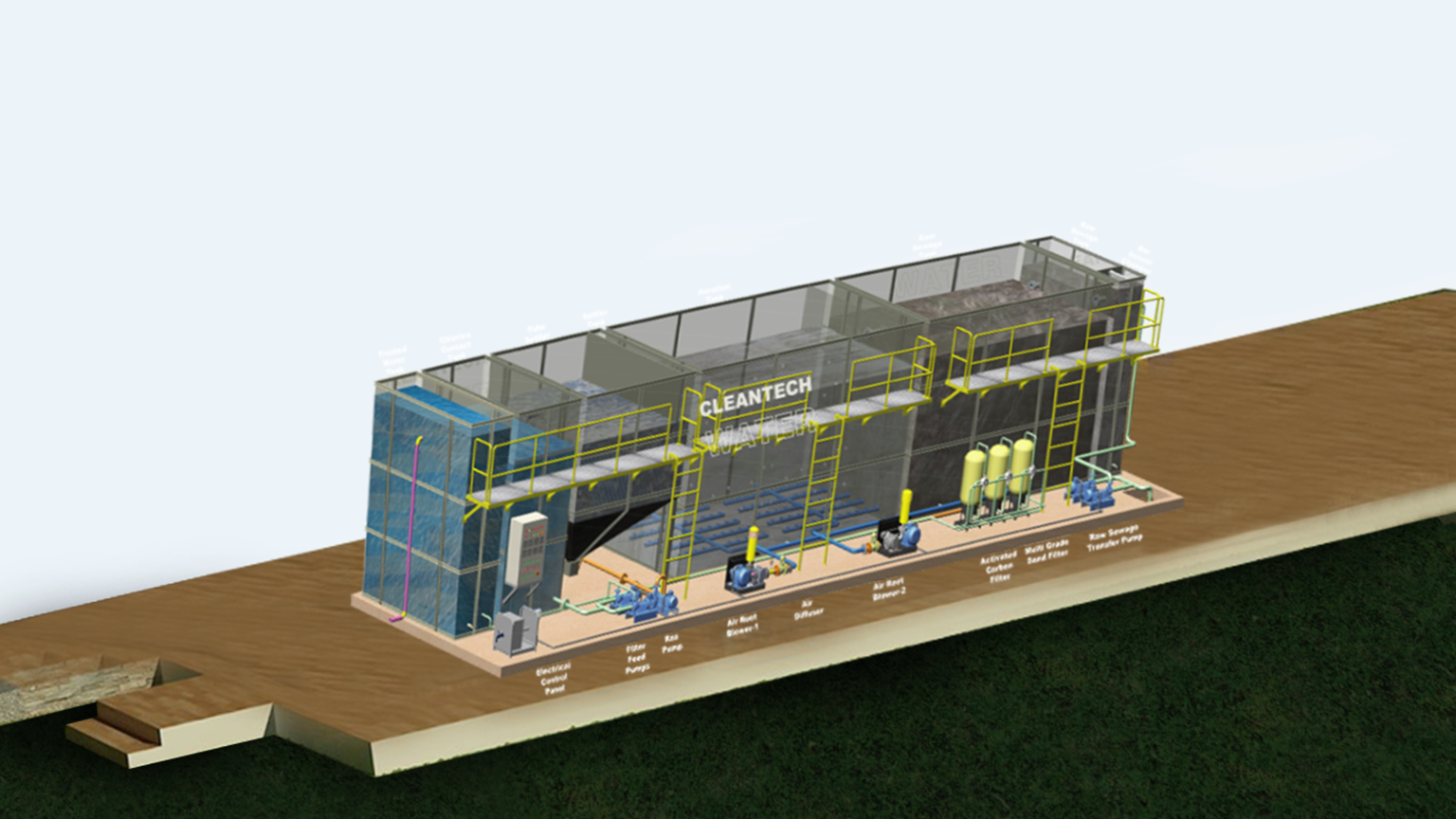

A packaged sewage treatment plant is a pre-engineered, modular unit designed to handle sewage and wastewater treatment compactly and efficiently. These systems are ideal for various applications, including residential, commercial, and industrial settings. They offer a scalable solution for treating wastewater effectively while minimising space and installation costs.

The Role of SCADA Systems in Wastewater Treatment

SCADA systems play a crucial role in modernising and streamlining the operation of packaged sewage treatment plants. These systems provide a comprehensive platform for monitoring and controlling the treatment process, ensuring the plant operates efficiently and meets regulatory standards. Here’s how SCADA systems enhance the functionality of the plants:

Real-Time Monitoring

SCADA systems enable real-time monitoring of various parameters within the sewage treatment process. Parameters such as flow rates, tank levels, and chemical dosages can be continuously tracked. This allows operators to promptly identify anomalies or issues, ensuring the plant runs smoothly and efficiently.

Automation and Control

One of the key benefits of integrating SCADA systems is the automation of routine tasks. SCADA systems can control pumps, valves, and other equipment based on preset conditions or real-time data. This reduces the need for manual intervention, minimises human error, and ensures consistent treatment processes.

Data Collection and Analysis

SCADA systems collect vast amounts of data from various sensors and instruments within the packaged sewage treatment plant. This data is stored and analysed to provide valuable insights into the plant’s performance. Operators can use this information to optimise processes, forecast maintenance needs, and make data-driven decisions to enhance overall efficiency.

Remote Access and Control

Modern SCADA systems offer remote access capabilities, allowing operators to monitor and control the plant from virtually anywhere. This is particularly beneficial for businesses with multiple locations or for those who require off-site oversight. Remote access ensures that issues can be addressed promptly, reducing downtime and improving operational reliability.

Alarm Management

SCADA systems are equipped with alarm management features that alert operators to potential issues or deviations from normal operating conditions. These alarms can be customised based on the severity of the issue, allowing for a quick response to prevent potential system failures or environmental violations.

Regulatory Compliance

Ensuring compliance with environmental regulations is a critical aspect of wastewater treatment. SCADA systems help maintain regulatory compliance by providing accurate and detailed records of the treatment process. These records can be used for reporting purposes and to demonstrate adherence to environmental standards.

Advantages of SCADA Integration in Packaged Sewage Treatment Plants

Integrating SCADA systems into packaged sewage treatment plants offers several advantages:

- Enhanced Efficiency: Automation and real-time monitoring improve the overall efficiency of the treatment process.

- Cost Savings: Reduced need for manual intervention and optimised processes lead to lower operational costs.

- Improved Reliability: Continuous monitoring and alarm management increase the reliability of the treatment plant.

- Scalability: SCADA systems can be easily scaled to accommodate growing needs or additional treatment units.

- Data-Driven Decisions: Detailed data analysis enables informed decision-making and process optimisation.

Choosing the Right SCADA System for Your Packaged Sewage Treatment Plant

Selecting the right SCADA (Supervisory Control and Data Acquisition) system for your packaged sewage treatment plant is crucial to ensuring optimal performance and reliability. Here are key factors to consider:

Compatibility

Compatibility is the cornerstone of a successful SCADA implementation. Ensure the SCADA system you choose integrates seamlessly with your existing equipment and technology. This includes compatibility with sensors, controllers, and other automation components. A system that aligns well with your current setup will minimise the need for costly upgrades or adjustments, facilitating a smoother transition and integration process.

Scalability

As your packaged sewage treatment plant operations grow, your SCADA system should be able to scale accordingly. Opt for a system designed to accommodate future expansions and increased data demands. Scalability ensures the SCADA system can handle additional processes or units without compromising performance. This flexibility is essential for adapting to evolving needs and long-term operational growth.

User Interface

An intuitive user interface is vital for effective operation and monitoring of your SCADA system. The system should feature a user-friendly dashboard that allows operators to easily navigate through various functions and data views. An accessible interface reduces training time and minimises the risk of errors, enabling staff to efficiently manage the treatment plant and respond swiftly to any issues.

Support and Maintenance

Reliable support and maintenance are critical for the ongoing success of your SCADA system. Choose a provider known for offering comprehensive support services, including troubleshooting, updates, and technical assistance. A robust support plan ensures any issues are promptly addressed, minimising downtime and maintaining the continuity of your treatment processes. Additionally, regular maintenance and system updates help to keep the SCADA system performing optimally and secure from potential vulnerabilities.

Invest in the Future with a Packaged Sewage Treatment Plant

Investing in a packaged sewage treatment plant with integrated SCADA technology is a smart choice for efficient, reliable, and cost-effective waste water treatment. Cleantech Water offers customized solutions to water treatment plants in India to enhance efficiency, scalability, and more.

Don’t settle for outdated technology—embrace the future with a sewage treatment plant that combines cutting-edge SCADA systems with robust treatment solutions. Whether you’re a property owner or a business, this investment will optimise your operations, reduce maintenance costs, and enhance overall efficiency.

Call us at +91-7935660299 or write to us at [email protected] to explore the benefits of advanced sewage treatment solutions and discover how our packaged systems can transform your wastewater management. Let’s work together to build a sustainable solution for your needs!