How Do You Choose the Right Chop Saw Measuring System for Your Needs?

Choosing the proper chop saw measuring gadget is crucial for precision, efficiency, and productivity in your slicing operations. This article...

Choosing the proper chop saw measuring gadget is crucial for precision, efficiency, and productivity in your slicing operations. This article explores ten key factors to consider whilst deciding on the pleasant device to fulfill your particular desires and make sure your workspace operates with maximum accuracy and manipulation.

1. Understand Your Cutting Requirements First

Before deciding on a chop saw measuring system, it is crucial to assess your specific slicing wishes. Consider the types of substances you commonly work with, their dimensions, and the way specific your cuts need to be. Some industries require tighter tolerances than others, and the wrong machine can result in waste, rework, or even protection issues. Think about whether or not you’re cutting metallic, wooden, plastic, or composites, as this influences what functions your measuring system must have. Understanding your workload, quantity of manufacturing, and complexity of jobs will form the premise for selecting the proper setup.

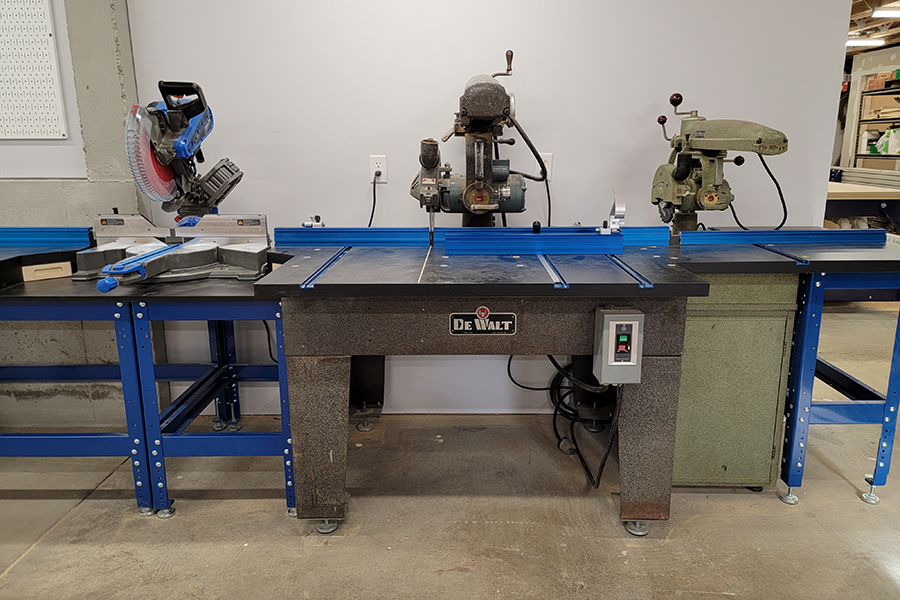

2. Evaluate the Type of Chop Saw You Use

Chop saws are available in numerous types, together with abrasive saws, bloodless saws, and miter saws. Each kind demands an exceptional approach to measurement and setup. Some measuring structures are designed to integrate specifically with positive saw types, imparting better accuracy and ease of use. For instance, a measuring system that pairs nicely with a chilly saw may not feature optimally with an abrasive saw because of the variations in vibration and blade movement. Ensuring compatibility with your existing chop saw version is essential for maximizing performance and heading off pointless adjustments.

3. Accuracy and Precision Are Critical Factors

Precision in reducing is not pretty much making accurate lengths; it’s approximately consistency and repeatability. A desirable measuring gadget should assist reduce human mistakes and provide dependable readings throughout more than one cuts. Look for a device with finely graduated scales or digital readouts that provide actual-time remarks. If your paintings involve tight tolerances, a digital measuring machine can also offer the high accuracy wished. Mechanical stops may work for fundamental projects, but superior applications benefit substantially from digital or laser-guided alternatives that ensure every cut meets specification.

4. Consider Manual vs. Digital Measuring Systems

When selecting a chop saw measuring machine, decide whether or not you want a manual or digital setup. Manual systems commonly use rulers, tape measures, and mechanical stops, which are greater low-cost however at risk of person error. Digital systems, however, provide better accuracy and faster setups. They frequently encompass programmable controls that make repetitive cuts faster and greater dependable. If you operate a high-extent workshop or fabrication facility, a virtual machine can substantially reduce labor time and improve product consistency. For hobbyists or low-volume use, manual systems might also suffice.

5. Think About Material Handling and Workflow

Your measuring machine needs to not simplest be correct however also facilitate clean workflow. Consider how substances may be fed into the saw and whether or not the measuring device aligns properly together with your setup. Systems that consist of conveyors, supports, or adjustable tables can substantially improve ergonomics and decrease operator fatigue. The period of the material being cut is likewise essential; if you’re running with massive or heavy stock, a device with incorporated support structures and material stops will assist hold constant measurements whilst improving protection. Streamlining cloth handling ensures that your group can keep speed without sacrificing fine.

6. Look for Durability and Build Quality

A measuring gadget must be durable enough to withstand the everyday rigors of your work environment. Whether you’re operating in a metal fabrication keep, woodshop, or construction website online, the device should be constructed from quality materials like aluminum, stainless-steel, or heavy-duty plastics. High-excellent systems resist put on and damage through the years, preserving their accuracy even after hundreds of cuts. Pay interest to the damage resistance of moving parts and the stability of mounting brackets or clamps. Choosing a well-constructed machine may cost greater first of all but can pay off in lengthy-term reliability and lower protection.

7. Assess Ease of Installation and Integration

An effective chop saw measuring gadget must be smooth to install and combine with your current gear. Some structures include everyday mounting alternatives, at the same time as others are logo- or model-particular. A system that calls for foremost changes or custom fittings may delay implementation or incur more fees. If you’re operating in a shared or rotating workspace, you may want a machine that can be fast removed and reinstalled. Also, verify how intuitive the setup is for operators. Systems with person-pleasant calibration and clean measurement publications will store time and decrease education overhead.

8. Check for Expansion and Upgrade Options

As your operation grows, your desires may also trade. Selecting a chop saw measuring machine with scalable alternatives will let you increase without starting from scratch. Some structures offer modular additives, digital upgrades, or software integrations which could beautify capability over time. For example, to start with a guide machine might be upgradable to a digital interface or compatible with automation additives. Ensuring that your investment supports destiny upgrades permits you to live competitively without large reinvestments. It additionally suggests that the producer is committed to ongoing innovation and customer support.

9. Review Brand Reputation and Customer Support

Before making a purchase, study the reputation of the manufacturer or vendor. A legitimate brand generally stands at the back of its merchandise with warranties, responsive customer service, and helpful resources including personal manuals, education films, and technical documentation. Reading reviews from industry peers or online forums can provide treasured insights into reliability and personal enjoyment. In instances in which troubleshooting or upkeep are wished, excellent customer service can make a massive difference. Choose a supplier who offers now not only a first-rate product but also the aid to keep your system strolling easily through the years.

10. Match Your Budget Without Sacrificing Essential Features

Finally, price is continually a thing in deciding on the proper measuring device. While it is tempting to pick out the cheapest option to be had, do not forget that a measuring system is an extended-time period funding in productivity and accuracy. Striking the right stability between fee and performance is fundamental. Consider what capabilities are non-negotiable to your workflow—such as digital readouts, automation compatibility, or heavy-responsibility creation—and allocate your finances as a consequence. Sometimes spending slightly more upfront can store money ultimately via reduced hard work, much less waste, and quicker turnaround instances. Explore financing options or vendor reductions if price range constraints are an issue.

Conclusion: Integrating the Right Solution for Maximum Performance

Choosing the proper chop saw measuring system calls for careful consideration of your slicing obligations, safe environment, and future growth. From figuring out the compatibility of your saw and preferred stage of accuracy to evaluating durability and improved options, each element plays a position in maximizing your operational efficiency. Whether you’re walking a small workshop or a big-scale production facility, the automatic saw system can remodel the way you technique cutting jobs. When incorporated with an automated saw system, an extremely good measuring setup can streamline operations, reduce human errors, and improve productivity. Investing inside the right tools today guarantees your success in assembling tomorrow’s needs with precision and confidence.