How AVEVA Edge SCADA Supports Real-Time Decision-Making in Industrial Settings

If your plant or facility still reacts to problems after they happen, you’re already too late. That delay costs time,...

If your plant or facility still reacts to problems after they happen, you’re already too late. That delay costs time, money, and sometimes safety. Real-time decisions aren’t just nice to have anymore—they’re expected. This is where AVEVA Edge SCADA steps in. At Pima Industrial, we’ve seen firsthand how this tool gives teams better control, faster response, and clearer data—all without extra stress.

Let’s break it down in simple words. Whether you’re in manufacturing, water treatment, or energy, you need one thing to stay competitive: instant, accurate control. AVEVA Edge SCADA helps make that happen.

What Is AVEVA Edge SCADA?

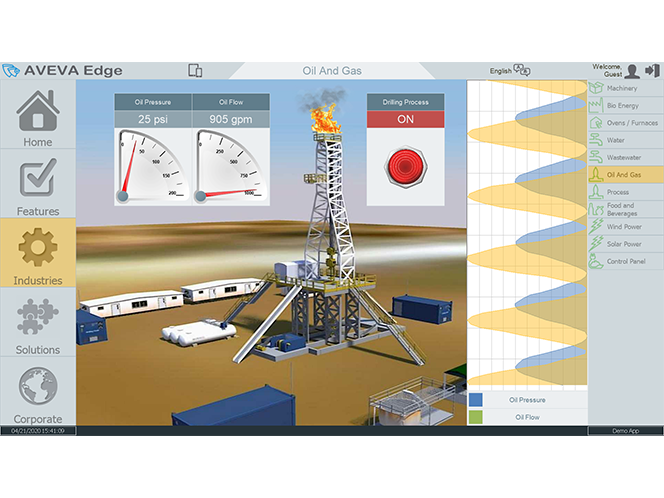

AVEVA Edge SCADA is a flexible software designed for industrial control systems. It helps monitor, control, and visualize data across machines, sensors, and equipment—right from one place. You can run it on small panels or full-size PCs.

It’s used in plants and remote stations where real-time feedback, alarms, and reporting can’t fail. It works with PLC systems, RTUs, and IoT devices, offering quick access to live data. For industries with moving parts and shifting conditions, that speed makes a big difference.

Why Real-Time Decision-Making Matters More Than Ever

Time equals money in industrial operations. Downtime leads to waste. Errors cause damage. And manual checks are too slow. Real-time data helps you fix things before they get worse—or avoid issues altogether.

Here’s how it helps:

- Detect equipment issues as they happen, not hours later

- Adjust operations on the fly

- Respond to safety risks immediately

- Make quick production changes based on demand

AVEVA Edge SCADA helps with all of these.

Key Features of AVEVA Edge SCADA That Enable Real-Time Control

Real-time decision-making needs tools that give instant updates, smart visuals, and quick reactions. AVEVA Edge SCADA comes packed with tools to do just that.

Built-in HMI Support

You can set up Human Machine Interfaces (HMIs) that display real-time stats, graphs, or alarms. Operators can spot problems fast and act without guesswork.

Real-Time Alarms and Events

When something goes wrong—pressure drops, temperature spikes, flow rates fall out of range—the system sends alerts right away. Alerts can go to local displays or mobile devices.

Multi-Protocol Support

AVEVA Edge SCADA supports many industrial communication protocols, like:

- Modbus

- OPC UA

- MQTT

- SNMP

This means you can connect it to many devices—without writing custom drivers.

Remote Access and Cloud Integration

Need to check data from outside the plant? AVEVA Edge SCADA allows remote access via web thin clients. Teams can view dashboards or receive alerts on the go.

Easy Scripting for Custom Logic

If you want to trigger specific actions when something happens, AVEVA Edge supports flexible scripting. You can set logic for shutdowns, alerts, or process changes without hard-coding.

Real-World Example: Water Plant Using AVEVA Edge SCADA

A mid-size water treatment plant in Arizona was losing time checking tank levels by hand. With AVEVA Edge SCADA, they added tank-level sensors, real-time dashboards, and remote monitoring.

Now, operators get instant alerts when water drops too low. They can adjust pumps within seconds, not hours. Downtime dropped by 27% within the first six months. Pima Industrial supported their full migration.

Common Decisions Made Faster with AVEVA Edge SCADA

Equipment Status Checks

Operators can see if a motor, valve, or sensor is online or failing—no need to wait for a shift report.

Batch Process Control

In food or chemical plants, small timing errors cause waste. AVEVA Edge SCADA gives control over batch cycles, helping improve yield.

Energy Monitoring

Teams can track how much power each unit uses in real time. If usage spikes, they can act fast to reduce load.

Environmental Safety

SCADA can track things like gas leaks, chemical spills, or air pressure issues. It helps reduce danger by cutting reaction time.

Secondary Benefits That Support Real-Time Decisions

While fast decisions are the goal, AVEVA Edge SCADA also gives your team tools that help in daily tasks.

Easy User Interface

Operators don’t need to be tech experts. The dashboards are clean and easy to use. This means less training time and fewer mistakes.

Better Historical Data

SCADA records past events. Teams can spot patterns and tweak systems to avoid common faults.

Custom Reporting

Need to send hourly or daily reports to managers? AVEVA Edge SCADA can auto-generate and email those without any manual input.

Who Should Use AVEVA Edge SCADA?

This software fits teams in industries like:

- Water & wastewater

- Food & beverage

- Oil & gas

- Building automation

- Manufacturing

- Energy & utilities

If your team needs clear, live feedback and faster responses, it’s worth a serious look.

Pros & Cons of AVEVA Edge SCADA

Pros

- Supports many device types

- Runs on small hardware

- Quick setup and updates

- Great for remote monitoring

- Strong community and support from Pima Industrial

Cons

- May need scripting for advanced logic

- Not suited for ultra-large enterprise deployments (AVEVA System Platform may be better there)

AVEVA Edge SCADA vs. Traditional SCADA Systems

| Feature | AVEVA Edge SCADA | Legacy SCADA |

|---|---|---|

| Real-Time Control | ✔️ Fast, responsive | ⚠️ Slower updates |

| Hardware Flexibility | ✔️ Runs on low-power PCs | ❌ Needs custom servers |

| Remote Access | ✔️ Browser & mobile support | ❌ Often local only |

| Setup Time | ✔️ Quick deployment | ❌ Time-consuming |

| Cost | ✔️ Cost-effective | ❌ High upfront costs |

Final Thoughts: The Smart Way to Run Industrial Systems

Real-time decisions can’t wait. If your team still depends on old systems or delayed data, it’s time to shift. AVEVA Edge SCADA gives you real-time control, alerts, remote access, and smart dashboards that help your team act fast and stay ahead.

At Pima Industrial, we help teams set up and fine-tune AVEVA Edge SCADA for everyday operations. You don’t need a large team or a big budget to run like a top-tier facility. You just need the right tool and the right support.

If you’re ready to cut downtime, improve safety, and react in real time—get in touch with Pima Industrial. We help teams like yours install, configure, and get the most out of AVEVA Edge SCADA.

👉 Let’s talk about your setup today.

FAQ

What is AVEVA Edge SCADA used for?

It helps monitor and control industrial systems in real-time, including equipment, sensors, and data flows.

Who uses AVEVA Edge SCADA?

Industries like water treatment, energy, food, and oil use it for fast data control and response.

Why is real-time data important in SCADA?

It allows operators to fix problems instantly, improve efficiency, and reduce downtime.

How does AVEVA Edge SCADA improve response time?

It sends alerts, updates dashboards, and allows control changes without delay.

Where is AVEVA Edge SCADA installed?

It runs on industrial PCs, embedded panels, or remote clients—on-site or off-site.

How does AVEVA Edge SCADA connect to devices?

It uses standard protocols like Modbus, OPC UA, and MQTT.

Will AVEVA Edge SCADA work with cloud systems?

Yes, it supports cloud integration for remote access and storage.

Can small teams use AVEVA Edge SCADA?

Yes, it’s ideal for small to mid-sized facilities due to its low resource needs.

What kind of data does AVEVA Edge SCADA handle?

It handles live sensor data, alarms, historical trends, reports, and operator inputs.

Is AVEVA Edge SCADA expensive?

Compared to full-scale SCADA platforms, it’s more cost-friendly and efficient for smaller needs.