How A-Frame BTEX Systems and Waste operation Tanks Optimize Oilfield Sustainability

Environmental regulations in the oil painting and gas sector continue to strain, demanding advanced results to minimize dangerous emigrations. ultramodern...

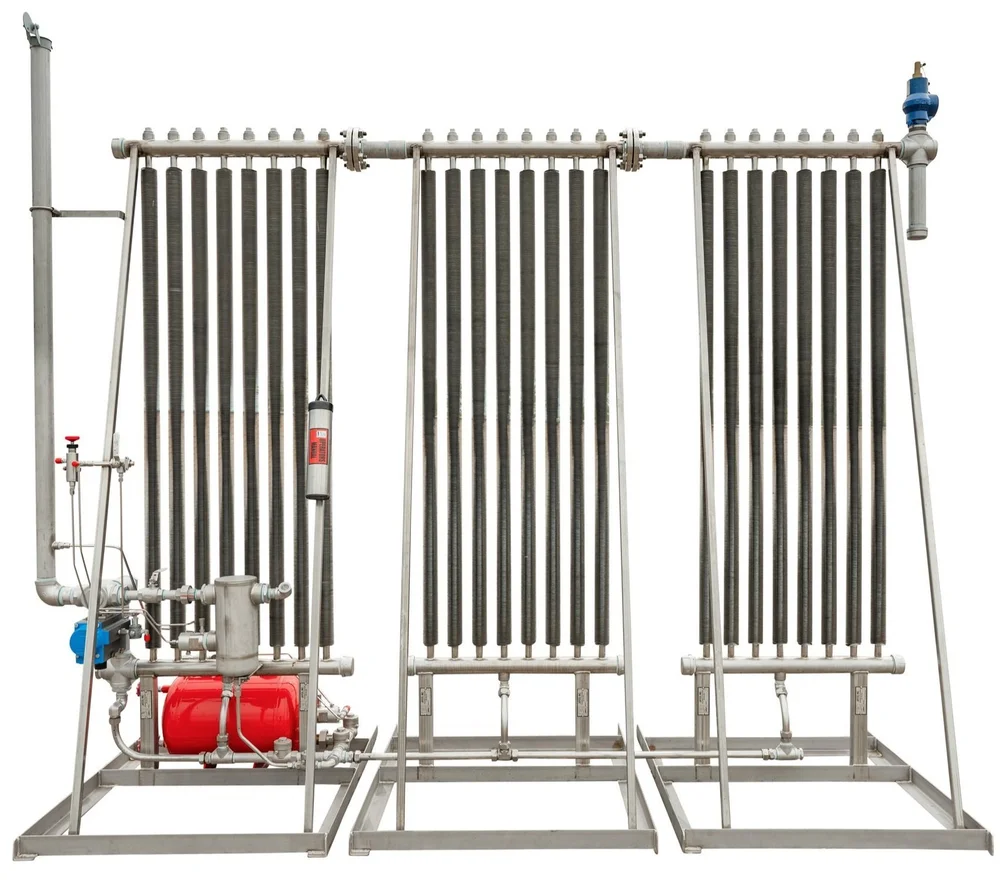

Environmental regulations in the oil painting and gas sector continue to strain, demanding advanced results to minimize dangerous emigrations. ultramodern systems are pivotal to landing unpredictable organic composites( VOCs) and icing safe storehouse of product fluids. Among these, A-Frame BTEX Systems have come a vital tool for drivers aiming to maintain compliance while perfecting functional effectiveness. reciprocal structure similar as waste operation tanks provides secure constraint of dangerous liquids, supporting both nonsupervisory adherence and safety. fresh technologies like jatco environmental tanks, jatco tanks, and the btex eliminator system enhance emigration control capabilities. Together with pollution control outfit for oil painting and gas, these results reflect a growing commitment to environmental sustainability in oil painting and gas assiduity operations.

Why Traditional Systems Fail to Meet Modern norms

heritage outfit frequently struggles to misbehave with ultramodern environmental conditions, performing in emigrations that exceed nonsupervisory thresholds. A-Frame BTEX Systems give a ultramodern volition, offering bettered VOC recovery from tanks, channels, and wastewater aqueducts. Integrating waste operation tanks ensures that dangerous substances are safely stored and managed, precluding accidental releases. Drivers decreasingly calculate on reciprocal results similar as jatco environmental tanks and jatco tanks to produce a completely integrated emigration control system. When paired with a btex eliminator system, these technologies significantly reduce environmental threat. Using ultramodern pollution control outfit for oil painting and gas is no longer voluntary — it is essential to achieve long- term environmental compliance for oil painting and gas while advancing environmental sustainability in oil painting and gas assiduity practices.

How A-Frame BTEX Systems Capture dangerous VOCs

A-Frame BTEX Systems excel at landing benzene, toluene, ethylbenzene, and xylene vapors before they escape into the atmosphere. Their technical design maximizes vapor recovery and minimizes emigration losses. These systems integrate seamlessly with waste operation tanks to contain and reuse captured fluids efficiently. fresh storehouse options like jatco tanks and jatco environmental tanks insure secure constraint, while the btex eliminator system farther reduces VOC emigrations at the source. These concerted results, along with other pollution control outfit for oil painting and gas, enable drivers to misbehave with regulations and enhance environmental sustainability in oil painting and gas assiduity issues.

Part of Waste operation Tanks in Environmental Compliance

Proper storehouse and operation of dangerous fluids are critical to maintaining safety and nonsupervisory compliance. Waste operation tanks give secure constraint, precluding leaks that could pollute soil and groundwater. When used alongside A-Frame BTEX Systems, these tanks insure that emigrations captured from product processes are safely stored and reused. Integrating jatco environmental tanks and jatco tanks creates a comprehensive fluid operation strategy. Coupled with a btex eliminator system, these results reduce emigrations, minimize environmental impact, and support broader pollution control outfit for oil painting and gas enterprise. enforcing these systems demonstrates a visionary commitment to environmental compliance for oil painting and gas.

Advantages of Combining BTEX Systems with Storage results

Functional effectiveness and compliance ameliorate when A-Frame BTEX Systems are combined with waste operation tanks. The tanks give dependable storehouse, allowing captured VOCs to be reused without threat of environmental impurity. Drivers also profit from enhanced monitoring capabilities and reduced conservation conditions. Using jatco tanks, jatco environmental tanks, and a btex eliminator system farther strengthens environmental controls. When paired with other pollution control outfit for oil painting and gas, this integrated approach provides harmonious results and contributes to long- term environmental sustainability in oil painting and gas assiduity pretensions.

Supporting functional trustability with Integrated Systems

Oilfield operations demand outfit that can repel harsh environmental conditions while maintaining high performance. A-Frame BTEX Systems are erected for continuity, icing VOC prisoner indeed under heavy use. Meanwhile, waste operation tanks are designed to safely store product fluids and help leaks. reciprocal storehouse results similar as jatco tanks and jatco environmental tanks ameliorate trustability and reduce time-out. Incorporating a btex eliminator system ensures that emigrations are controlled at every stage. When combined with pollution control outfit for oil painting and gas, drivers can meet compliance conditions efficiently while promoting environmental sustainability in oil painting and gas assiduity enterprise.

How Integrated Systems Minimize Environmental threat

Accidental releases of hydrocarbons and VOCs can pose serious environmental and legal pitfalls. Using A-Frame BTEX Systems alongside waste operation tanks mitigates these pitfalls by landing and safely storing dangerous emigrations. Supplementary results like jatco tanks and jatco environmental tanks produce fresh layers of constraint. The btex eliminator system farther reduces the liability of VOC release. Together with other pollution control outfit for oil painting and gas, these technologies insure that operations misbehave with environmental norms, enhancing overall environmental compliance for oil painting and gas and promoting environmental sustainability in oil painting and gas assiduity practices.

Enhancing Energy Efficiency in Oilfield Operations

Energy effectiveness is a critical factor for sustainable oilfield operations. A-Frame BTEX Systems reduce emigrations while minimizing energy consumption compared to aged VOC control styles. Waste operation tanks reduce the need for frequent fluid transfers and associated energy use. fresh outfit, including jatco tanks, jatco environmental tanks, and a btex eliminator system, support effective fluid running and emigration control. These results integrate with other pollution control outfit for oil painting and gas to optimize overall system performance. By reducing energy consumption and environmental impact, drivers advance environmental sustainability in oil painting and gas assiduity enterprise while lowering functional costs.

Scalable results for Growing Oilfield Demands

Product volumes in oilfields can change, taking systems that gauge efficiently. A-Frame BTEX Systems are designed with modularity in mind, allowing drivers to expand capacity as demanded. Waste operation tanks are available in multiple sizes to handle adding volumes of stored liquids. By incorporating jatco tanks, jatco environmental tanks, and a btex eliminator system, drivers can acclimate storehouse and emigration control systems to match product conditions. When integrated with other pollution control outfit for oil painting and gas, these scalable results insure continued environmental compliance for oil painting and gas and support evolving environmental sustainability in oil painting and gas assiduity strategies.

Long- Term conservation Benefits of Modern Systems

Maintaining functional effectiveness while reducing conservation costs is a precedence for oilfield drivers. A-Frame BTEX Systems are designed for continuity and low- conservation performance, minimizing service interruptions. Waste operation tanks give secure constraint, reducing the threat of leaks and tumbles that bear expensive remittal. Using jatco tanks, jatco environmental tanks, and a btex eliminator system helps minimize routine conservation and ameliorate system trustability. Integrating these results with other pollution control outfit for oil painting and gas supports functional durability and strengthens environmental sustainability in oil painting and gas assiduity sweats.

How ultramodern Systems Support Regulatory Compliance

Regulatory bodies decreasingly concentrate on reducing VOC emigrations, hydrocarbon leaks, and other environmental hazards. A-Frame BTEX Systems give high- effectiveness vapor prisoner to meet nonsupervisory norms. Waste operation tanks insure that dangerous fluids are securely stored, reducing threat of environmental violations. fresh measures similar as jatco environmental tanks, jatco tanks, and a btex eliminator system produce an intertwined compliance network. When paired with advanced pollution control outfit for oil painting and gas, these results help drivers meet and exceed environmental prospects. By supporting strong environmental compliance for oil painting and gas, these systems demonstrate commitment to environmental sustainability in oil painting and gas assiduity enterprise.

Conclusion

For oil painting and gas drivers, integrating A-Frame BTEX Systems with waste management tanks provides a robust frame for emigration control, safe storehouse, and compliance. reciprocal technologies similar as jatco tanks, jatco environmental tanks, btex eliminator system, and other pollution control outfit for oil painting and gas insure drivers can meet strict regulations while enhancing sustainability. This integrated approach improves effectiveness, reduces environmental pitfalls, and supports long- term environmental sustainability in oil painting and gas assiduity pretensions. Companies like Jatco Inc lead in delivering these advanced, scalable results that unborn- evidence oilfield operations while maintaining strict environmental responsibility.

FAQ

What are A-Frame BTEX Systems used for?

They capture VOCs similar as benzene, toluene, ethylbenzene, and xylene from oilfield operations.

Why are waste operation tanks important?

They safely store dangerous fluids, precluding leaks and guarding soil and groundwater.

How do BTEX systems integrate with other environmental outfit?

They work with storehouse tanks, btex eliminator systems, and pollution control outfit to insure comprehensive emigration operation.

Do these systems support nonsupervisory compliance?

Yes, they help drivers meet environmental norms and reduce emigrations at the source.

How do these results promote sustainability in oil painting and gas operations?

By minimizing emigrations, reducing energy consumption, and furnishing secure fluid storehouse, drivers support long- term sustainability.