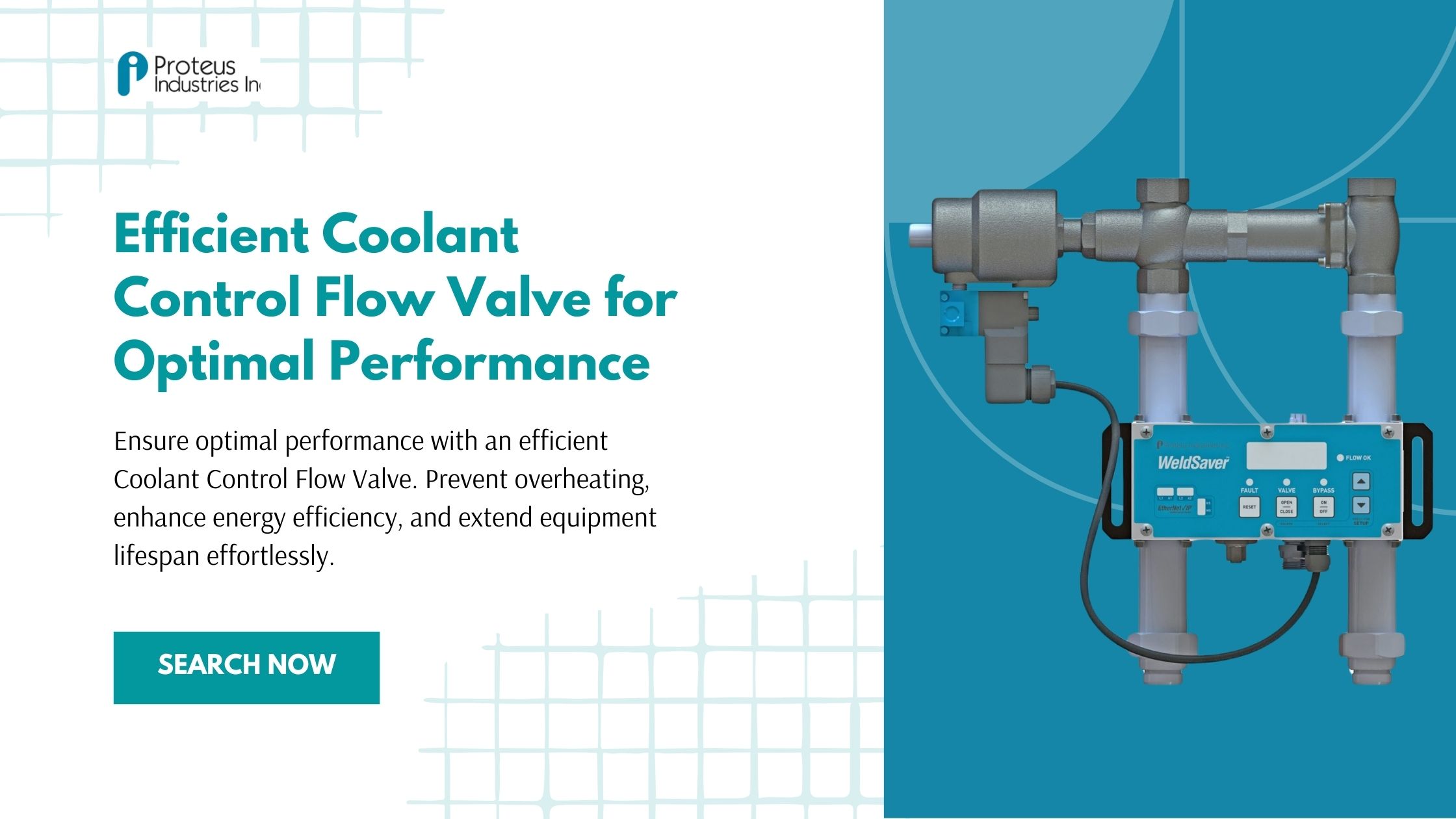

Efficient Coolant Control Flow Valve for Optimal Performance

In industrial settings where maintaining optimal temperatures is essential, a Coolant Control Flow Valve plays a key role in ensuring...

In industrial settings where maintaining optimal temperatures is essential, a Coolant Control Flow Valve plays a key role in ensuring equipment runs efficiently and lasts longer. These coolant flow valve ensuring that machinery operates at the correct temperature to prevent overheating and optimize performance. Among the leading manufacturers in this field, Proteus Industries Inc. it has been at the forefront of delivering innovative solutions, including the WeldSaver™ 6 Legacy Series, designed specifically for welding applications.

Importance of Coolant Control Flow Valves in Industrial Applications

Coolant control flow valves are critical components to industries like automotive, aerospace, power generation, and manufacturing. Its main function is to make sure heat-sensitive elements stay within a secure operating temperature by controlling coolant distribution properly.

1. Preventing Overheating and Equipment Damage

One of the benefits of using a coolant control flow valve is preventing overheating, which can cause severe damage to equipment. In welding applications, excessive heat can lead to warping, defects, and inefficiencies. The WeldSaver™ 6 Legacy Series by Proteus Industries Inc. is specifically designed to monitor coolant flow and detect leaks in real time, preventing equipment failures.

2. Enhancing Energy Efficiency

Efficient management of coolants lowers the amount of energy used to cool systems, thus making huge cost reductions. An efficiently designed coolant control flow valve maximizes cooling operations, conserving energy while delivering maximum performance.

3. Leak Detection and System Protection

Coolant system leaks can be problematic, resulting in wastage, equipment breakdown, and safety risks. Precise detection of leaks is offered by WeldSaver 6 Legacy Series, which automatically cuts off coolant supply when a leak is found. This is not only avoids downtime but also aids in meeting safety standards.

4. Prolonging Equipment Lifespan

By regulating temperatures, coolant control flow valves extend the lifespan of machinery and components. Materials can degrade and wear due to excessive heat if not properly regulated over a long period, but effective coolant regulation prevents this.

Features of the WeldSaver™ 6 Legacy Series

The WeldSaver™ 6 Legacy Series by Proteus Industries Inc. is an advanced solution designed to improve the efficiency of coolant systems in welding operations. The following main key features include:

Real-time Monitoring: Ongoing monitors coolant flow rate and temperature to provide get optimum performance.

Leak Detection and Auto Shut-off: Automatically detects leaks and shuts off coolant flow to avoid damage.

High Accuracy and Precision: Provides uniform coolant flow for high-quality welding outcomes.

User-Friendly Interface: Simple integration with existing systems for effortless use.

Long-Lasting Construction: Designed to perform in rough industrialies environments.

Applications of Coolant Control Flow Valves

1. Automotive Industry

In automotive production, proper coolant flow is important in welding and engine cooling operations. A Coolant Control Flow Valve provides accurate cooling, enhancing performance and production efficiency.

2. Aerospace Engineering

Aerospace components require precise thermal management to maintain structural integrity. Coolant control flow valves play a important role in cooling turbine components, welding processes, and other high-precision applications which use coolant flow valve.

3. Power Generation

In power plants, turbines, generators, and other equipment require consistent cooling to function effectively. By optimizing coolant flow, these valves enhance energy efficiency and reliability.

4. Industrial Manufacturing

From robotics to metal fabrication, coolant control flow valves help maintain precision and product quality. The WeldSaver™ 6 Legacy Series is particularly useful in robotic welding applications, ensuring continuous monitoring and protection against system failures.

Choosing the Right Coolant Control Flow Valve

When selecting a coolant control flow valve, consider the following factors:

- Flow Rate Requirements: Ensure that valve can handle the required coolant volume.

- Leak Detection Capabilities: Advanced valves like the WeldSaver™ 6 Legacy Series provide real-time leak detection and shut-off features.

- Durability and Compatibility: The valve should be compatible with your system and built to withstand industrial conditions.

- Automation and Control Features: Valves with automated monitoring reduce manual intervention and improve efficiency.

Conclusion

A Coolant Control Flow Valve is impotant part for maintaining the efficiency, safety, and longevity of industrial equipment. Proteus Industries Inc. has set a benchmark in coolant management with solutions like the WeldSaver™ 6 Legacy Series, which are ensures optimal performance, leak detection, and precision cooling in welding and other industrial applications. Investing in high-quality coolant control flow valves not only enhances operational efficiency but also prevents costly equipment failures.

For industries looking to improve their cooling systems, choosing a trusted provider like Proteus Industries Inc. ensures reliability and innovation in thermal management solutions.