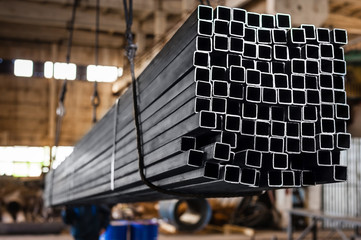

Where is Square Tubing Used? Exploring the Versatility of Square Steel Tubing in Modern Applications

Square tubing has earned its vicinity as one of the maximum versatile additives in present day creation and manufacturing. Known...

Square tubing has earned its vicinity as one of the maximum versatile additives in present day creation and manufacturing. Known for its easy edges, structural uniformity, and incredible load-bearing capability, square tubing is generally visible in architectural frameworks, commercial system, agricultural structures, and infrastructure initiatives. When fabricated from metal, this cloth turns into even more durable, presenting long-term strength and resistance to corrosion, effect, and strain. If you’re sourcing substances for a undertaking, the function of square steel tubing is one that can’t be neglected. Its reliability, mainly in structural frameworks, makes it a pinnacle desire amongst engineers, architects, and manufacturers. With call for growing, it’s no longer unusual to locate diverse options via steel vendors close to you, presenting a number of sizes, wall thicknesses, and steel grades tailor-made to particular mission desires.

Square Tubing inside the Construction Sector

One of the most common makes use of of square metal tubing is within the creation region. Its ability to offer both structural stability and aesthetic uniformity makes it distinctly suitable for architectural elements, building frames, and commercial systems. Because of its symmetrical shape, square tubing is easy to enroll in, reduce, and weld, streamlining production timelines and decreasing hard work costs.

From assist columns in parking systems to load-bearing frames in business warehouses, square tubing offers a balance of energy and performance. In high-upward push homes, it may be used for vertical supports or as a part of the skeletal body. Its easy lines also make it an appealing option for uncovered structural elements in modern-day architectural designs.

Additionally, its compatibility with concrete and other constructing substances similarly amplifies its attraction. Whether used independently or as a reinforcement element, rectangular tubing gives the power needed to meet each engineering and aesthetic requirements.

Application of Square Tubing in Industrial Manufacturing

Industrial environments require components that could deal with regular strain, vibration, and heavy loads. Square steel tubing fits this profile, making it a famous desire in production system, gadget bases, racking structures, and conveyor frameworks. Its form lends itself properly to rigid, repeatable systems, reducing the danger of failure under working pressure.

Manufacturers frequently rely on rectangular tubing for modular assemblies, as its shape lets in for stable fastening and alignment. In manufacturing environments wherein machinery is frequently moved or adjusted, the sturdiness of steel rectangular tubing offers lengthy-time period reliability. It additionally holds up nicely in harsh commercial situations, consisting of exposure to chemical substances and high warmness.

Additionally, metallic tubing is frequently fabricated in bulk to fulfill repetitive manufacturing needs. Its smooth fabrication and flexibility suggest that manufacturers can adjust or reflect elements speedy with out compromising the power or satisfactory of the product.

Square Tubing in Agricultural Equipment and Infrastructure

Agricultural settings gift particular environmental challenges together with moisture, temperature fluctuations, and mechanical impact. Square metal tubing is frequently used to assemble fencing, greenhouse frames, irrigation structures, and gadget trailers because of its durability and resistance to rust.

Farmers and device producers alike select square tubing for farm animals enclosures, gate structures, and framing elements on machinery. In irrigation systems, rectangular tubing serves as a support factor for pipelines and sprayers. The capacity to face up to out of doors situations over lengthy durations ensures the sturdiness of agricultural infrastructure with minimum maintenance.

Furthermore, as agriculture continues to modernize, the use of prefabricated metallic structures has grown. Square tubing allows quick assembly and gives sturdy aid for shelters, feed storage, and crop protection gadgets, mainly in huge-scale farming operations.

Role of Square Tubing in Transportation and Logistics

Transportation system—together with trailers, shipment frames, and rail structures—frequently relies upon on the electricity and shape of square steel tubing. Its aggregate of lightweight and inflexible structure makes it appropriate for mobile programs in which both energy and mobility are crucial.

Cargo trailers, truck beds, and material coping with bins often make use of square tubing to shape the foundational shape that helps loads all through transit. The tubing’s resistance to deformation under dynamic pressure guarantees that transported substances stay solid and steady.

In logistics warehouses and freight terminals, rectangular tubing is likewise used in shelving systems and automatic racking. These structures ought to keep heavy weights even as imparting the modularity required for efficient space utilization. As a result, rectangular tubing turns into the backbone of many logistical frameworks.

Artistic and Architectural Uses of Square Tubing

While square steel tubing is maximum usually visible in structural and commercial packages, it also finds an area in creative layout. Architects and designers admire its cutting-edge aesthetic, especially while used in exposed frameworks, handrails, or fixtures.

Sculptors and installation artists also price rectangular tubing for its potential to shape geometric structures and preserve integrity in massive-scale outdoor displays. Its smooth lines complement minimalistic and commercial design themes, making it a fave in city landscape initiatives and public installations.

In industrial interiors, square tubing is often left exposed as a part of a building’s layout language. This desire celebrates the shape’s rawness and functionality while additionally serving a practical function in supporting partitions, ceilings, and lights installations.

The Importance of Local Sourcing and Fabrication

When assignment a production or production undertaking, timely get right of entry to to brilliant materials is crucial. That’s why many specialists flip to metal vendors near you for quick, fee-powerful answers. Local sourcing reduces delays, transportation costs, and logistical complexities, making it easier to live on time table.

Working with close by steel providers also lets in for better best manage. It will become easier to affirm specs, request customization, and obtain expert recommendation on fabrication approaches. Additionally, having direct get admission to to rectangular tubing stock ensures that any closing-minute adjustments or extended needs can be controlled without halting project progress.

Custom cuts, hole drilling, and completing treatments also are simpler to coordinate whilst running with neighborhood fabricators. This hands-on approach simplifies procurement and minimizes the risks related to long-distance delivery or deliver chain disruptions.

Environmental Advantages of Steel Tubing Use

As the development and manufacturing industries area greater emphasis on sustainability, metal tubing—inclusive of rectangular variations—has verified to be a recyclable and long-lasting alternative. Steel can be recycled with out dropping its structural properties, making rectangular tubing a sustainable fabric desire.

In packages where longevity and minimal environmental impact are priorities, rectangular steel tubing affords a compelling answer. Whether utilized in temporary scaffolding or permanent systems, its reusability and low maintenance make it both economically and environmentally sound.

Moreover, many cutting-edge centers aim to reduce construction waste by using incorporating recyclable substances into their design. Square tubing, which frequently originates from recycled resources, supports this initiative even as providing the same performance as newly fabricated metallic.

Integration with Other Structural Steel Products

Square tubing regularly works in tandem with different structural metallic merchandise, creating included frameworks that beautify common stability. It is frequently paired with I-beams, channels, angles, and flat bars to complete load-bearing systems in buildings, equipment, and vehicles.

By using a aggregate of shapes and profiles, engineers can design custom answers that suit specific mechanical demands. Square tubing provides steady geometry and easy connection points, simplifying meeting while used alongside different metallic additives.

In prefabricated homes or system frames, square tubing regularly bureaucracy the base layer upon which different structural steel factors are introduced. This synergy contributes to the structural integrity of complicated designs whilst keeping flexibility for future upgrades or expansions.

Conclusion: The Essential Role of Square Tubing in Today’s Projects

From towering buildings to compact machinery, square tubing performs a critical function in shaping the built environment. Its adaptability, strength, and aesthetic attraction make it a dependable aspect throughout limitless industries. Whether you are constructing a warehouse, assembling a piece of equipment, or designing a completely unique architectural characteristic, square steel tubing offers unrivaled benefits in each shape and characteristic.

With increasing availability through metal distributors near you, getting access to the right form of square tubing has by no means been less complicated. This accessibility, blended with the cloth’s validated overall performance, ensures it’ll remain a pass-to solution for engineers, architects, and developers for years to come. As demands develop and design standards evolve, square tubing stays a essential hyperlink among innovation and infrastructure.