How AVEVA SCADA Software Optimizes Real-Time Plant Operations

In today’s fast-paced manufacturing environment, plant managers need more than just data—they need insights, speed, and control. AVEVA software, especially...

In today’s fast-paced manufacturing environment, plant managers need more than just data—they need insights, speed, and control. AVEVA software, especially its SCADA solution, empowers businesses to manage real-time operations with unmatched efficiency. Whether you’re running a factory floor or a complex multi-site operation, AVEVA software solution delivers visibility, control, and performance where it matters most.

Let’s explore how this smart platform helps optimize every second of plant operations, what makes it unique, and why companies like yours are turning to Pima for implementation and support.

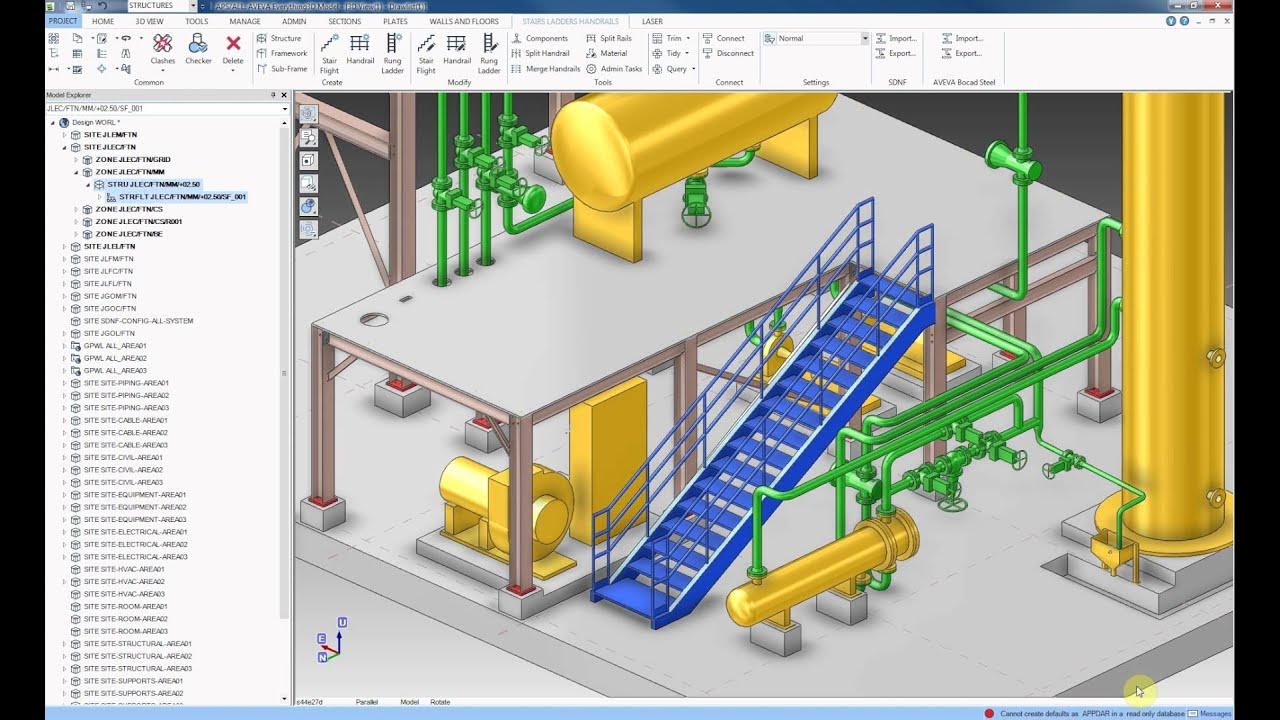

What Is AVEVA SCADA Software?

AVEVA SCADA software is a powerful supervisory control and data acquisition system. It allows industries to monitor, visualize, and control plant operations from a centralized interface. Unlike basic monitoring tools, AVEVA SCADA delivers advanced features that let operators act in real time, adjust systems instantly, and prevent costly disruptions.

Key Features of AVEVA SCADA Software

Real-Time Monitoring

Operators get a complete view of plant operations—live. Every sensor, device, and system is tracked and displayed in real time.

Advanced Alarm Handling

The software alerts teams instantly when something goes wrong, allowing for immediate correction before issues escalate.

Scalable Architecture

From small setups to massive industrial systems, AVEVA SCADA adapts without costly changes or reprogramming.

Centralized Control

Control multiple processes, machines, and facilities through one unified interface, saving time and improving accuracy.

Seamless Integration

It connects with existing PLCs, ERP systems, and databases, ensuring a smooth and connected ecosystem.

Historical Data Logging

AVEVA doesn’t just show what’s happening—it stores what happened and why, helping you prevent future issues.

How AVEVA SCADA Software Optimizes Real-Time Plant Operations

Faster Decision-Making

Operators and managers gain real-time insights that support immediate, informed decisions. No guesswork. No delay.

Downtime Reduction

Instant alerts and live dashboards help teams respond to anomalies before they impact production, keeping lines running.

Greater Efficiency

Automation reduces manual tasks, improves consistency, and frees up teams to focus on high-impact work.

Improved Quality

With accurate data, operators maintain product quality standards, identify deviations early, and reduce scrap.

Better Compliance

With detailed logs and real-time alerts, your plant stays compliant with safety and environmental standards.

How Different Industries Use AVEVA SCADA

Food and Beverage

Maintains strict hygiene and process controls, prevents contamination, and ensures consistent batch quality.

Pharmaceuticals

Supports high-precision manufacturing, documentation, and audit compliance—critical for regulatory success.

Water and Wastewater

Monitors flow, chemical levels, and pump stations in real time, ensuring safe water delivery and treatment.

Energy and Utilities

Manages generation, distribution, and load balancing for uninterrupted power supply and energy savings.

Manufacturing

Coordinates complex production lines, tracks every unit, and ensures optimal use of equipment and labor.

Why Businesses Choose AVEVA Software Solution from Pima

Expertise

Pima brings years of experience in implementing AVEVA solutions across industries. We don’t just sell software—we deliver success.

Support

From configuration to ongoing optimization, our technical teams are there at every step of your automation journey.

Training

We provide hands-on training to ensure your team knows how to get the most out of your AVEVA SCADA system.

Local Presence

Being close to our clients means faster response, real-time support, and better understanding of regional needs.

Pros and Cons of Using AVEVA SCADA Software

| Pros | Cons |

|---|---|

| Real-time insights | Requires initial setup time |

| Advanced alarm and event handling | Needs trained staff for setup |

| Scalable across industries | Upfront investment may be high |

| Integration with other platforms | Network reliability is critical |

| Improves safety and compliance | Complexity for very small ops |

Common Questions About AVEVA SCADA Software

Who should use AVEVA SCADA software?

Plant operators, automation engineers, and production managers across industries.

What makes it different from other SCADA systems?

It’s scalable, customizable, and integrates with a wide range of industrial systems.

Where can I get AVEVA SCADA software?

From certified distributors like Pima, who also offer support and integration services.

Why is real-time monitoring important?

Because delays in action can cost thousands in downtime or damage.

How does Pima help with implementation?

We provide end-to-end service—from planning to deployment, support, and training.

Will it work with my existing systems?

Yes, AVEVA SCADA is designed to integrate smoothly with your current infrastructure.

Final Thoughts

AVEVA software isn’t just another industrial tool—it’s the foundation of smarter, faster, and safer plant operations. When deployed with the right partner like Pima, the AVEVA software solution becomes a game-changer. It brings real-time control, reduces operational risk, and drives productivity across the board. As competition grows and margins shrink, efficiency isn’t optional—it’s everything.

If you’re looking to improve how your plant runs, reduce costs, and stay ahead of the curve, now’s the time to act. Pima can help you unlock the full potential of AVEVA SCADA software and tailor it to your exact needs.

Ready to see it in action?

Talk to our automation experts or schedule a free demo today.

Your real-time transformation starts now.