What Makes Industrial Painting a Crucial Investment for Facility Longevity?

Industrial facilities face constant exposure to harsh environmental conditions, corrosive chemicals, and heavy operational demands. Without proper protective measures, these...

Industrial facilities face constant exposure to harsh environmental conditions, corrosive chemicals, and heavy operational demands. Without proper protective measures, these structures deteriorate rapidly, leading to costly repairs and operational disruptions. Industrial painting serves as the first line of defense against these destructive forces, making it an essential investment for any facility manager or business owner.

Why Does Proper Surface Protection Matter for Industrial Assets?

Manufacturing plants, warehouses, and processing facilities operate in challenging environments that accelerate structural degradation. Metal surfaces corrode when exposed to moisture, chemicals, and temperature fluctuations. Concrete floors crack under heavy machinery loads. Without protective coatings, facility owners face premature equipment replacement and extensive renovation costs.

Professional industrial painting contractors apply specialized coatings that create impermeable barriers against corrosion, chemical damage, and weathering. These protective systems extend asset lifespan significantly, often doubling or tripling the operational life of structural components. The initial investment in quality coatings pays substantial dividends through reduced maintenance requirements and delayed capital expenditures.

How Do Environmental Factors Impact Facility Deterioration?

Industrial environments present unique challenges that standard commercial properties rarely encounter. High humidity levels accelerate rust formation on steel structures. Chemical vapors attack unprotected surfaces, causing premature failure. Temperature extremes cause expansion and contraction cycles that crack protective barriers.

Environmental factors requiring specialized protection include:

- Chemical exposure from manufacturing processes

- Temperature fluctuations exceeding normal ranges

- High humidity and moisture accumulation

- Salt air exposure in coastal facilities

- Ultraviolet radiation degrades surface materials

Industrial painting addresses these specific threats through carefully selected coating systems. Epoxy formulations resist chemical attack, while specialized primers prevent moisture penetration. Heat-resistant coatings maintain integrity at elevated temperatures, ensuring continuous protection even under extreme operating conditions.

What Role Does Industrial Painting Play in Safety Compliance?

Modern industrial facilities must meet stringent safety regulations that often mandate specific coating requirements. Fireproof coatings provide critical fire resistance, slowing flame spread and allowing safe evacuation. Anti-slip floor coatings reduce workplace accidents in high-traffic areas. Reflective paints improve visibility and help identify safety zones.

Industrial painters in Toronto understand local building codes and safety requirements. They ensure coating applications meet or exceed regulatory standards, protecting businesses from liability issues and regulatory penalties. This compliance aspect makes professional application essential rather than optional for many industrial operations.

Safety-related coating applications include:

- Intumescent fireproof coatings for structural steel

- Anti-slip epoxy floor systems in wet areas

- High-visibility markings for emergency egress routes

- Chemical-resistant coatings in processing areas

How Does Professional Application Ensure Long-Term Performance?

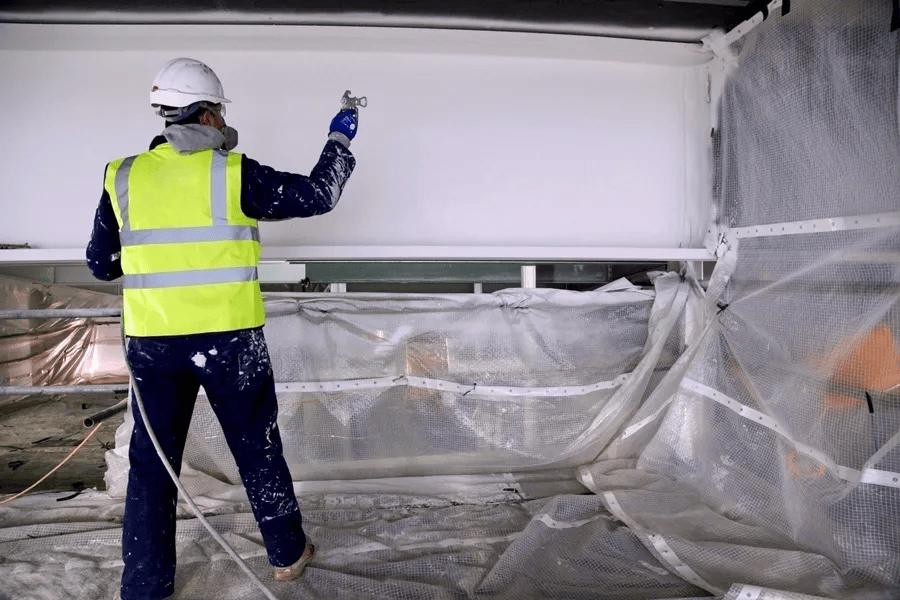

Surface preparation represents the most critical factor in coating longevity. Amateur applications often fail prematurely due to inadequate cleaning, improper primer selection, or environmental timing issues. Professional painting contractors in Toronto possess specialized equipment and technical knowledge necessary for optimal results.

Proper application begins with comprehensive surface analysis and preparation. This includes sandblasting to remove existing coatings, power washing to eliminate contaminants, and primer application under controlled conditions. Each coating layer requires specific temperature and humidity ranges for proper curing, factors that experienced painting companies in Toronto monitor continuously.

The technical expertise extends to coating selection based on specific environmental exposures. Different formulations provide optimal performance against particular threats, requiring detailed knowledge of material properties and application techniques. This specialized knowledge ensures maximum return on coating investments through extended service life and reduced maintenance requirements.

What Economic Benefits Result From Strategic Coating Investments?

Preventive coating applications cost significantly less than reactive repairs or premature replacements. A properly applied industrial coating system typically costs 10-15% of structural replacement expenses while providing decades of protection. This favorable cost-benefit ratio makes industrial painting one of the most effective facility maintenance investments available.

Beyond direct cost savings, protective coatings minimize operational disruptions. Planned maintenance activities cause less downtime than emergency repairs. Facilities can schedule coating applications during routine shutdowns, avoiding unplanned production losses that emergency structural repairs typically require.

Energy efficiency improvements represent additional economic benefits. Reflective roof coatings reduce cooling loads in hot climates. Insulative coatings help maintain process temperatures more efficiently. These operational savings accumulate over time, further improving the investment return on professional coating applications.

Which Industries Benefit Most From Professional Coating Services?

Manufacturing facilities experience some of the harshest operating conditions, making them prime candidates for specialized coating protection. Food processing plants require sanitizable surfaces that resist frequent washdowns. Chemical plants need coatings that withstand aggressive chemical exposures. Automotive facilities demand durable finishes that maintain appearance standards.

Warehousing and distribution centers benefit from floor coatings that resist forklift damage and facilitate easy cleaning. Oil and gas facilities require fire-resistant coatings that meet strict safety standards. Each industry presents unique challenges that require specialized coating knowledge and application techniques.

Multi-residential and commercial properties also benefit from industrial-grade coating systems, particularly in high-wear areas like parking garages, mechanical rooms, and exterior facades. The durability advantages of industrial coatings make them cost-effective solutions for any property experiencing heavy use or harsh environmental exposure.

Moving Forward With Your Facility Protection Strategy

Industrial painting represents a strategic investment that protects valuable assets while ensuring regulatory compliance and operational efficiency. The key lies in partnering with experienced professionals who understand the technical requirements and application challenges specific to industrial environments.

Quality coating systems require proper material selection, surface preparation, and application techniques that only specialized contractors can provide. The initial investment pays dividends through extended asset life, reduced maintenance costs, and improved operational reliability.

Protect your industrial facility with professional-grade coating solutions by partnering with experienced specialists. Contact Induspray today to discuss your industrial painting requirements and receive a detailed estimate tailored to your specific facility needs. Experience the difference that specialized expertise brings to your critical industrial assets.