PCB Repair Cost Breakdown: Essential Insights for OEMs

When a Printed Circuit Board (PCB) fails, OEMs are faced with a critical decision: repair or replace? While replacement might...

When a Printed Circuit Board (PCB) fails, OEMs are faced with a critical decision: repair or replace? While replacement might seem like the fastest solution, it’s often the most expensive—particularly for specialized or multilayer boards used in complex systems.

In contrast, PCB repair can restore functionality at a fraction of the cost. However, the actual PCB repair cost depends on several technical and logistical variables that many OEMs overlook.

For electronics manufacturers, the cost goes beyond just the repair invoice. Factors like downtime, hidden costs, and repair quality can significantly affect the total operational impact.

In this article, we’ll provide a detailed PCB repair cost breakdown, compare it to replacement options, and offer actionable strategies OEMs can use to reduce expenses while maintaining product reliability.

✅ Key Takeaways

- The PCB repair cost is shaped by board complexity, fault types, and availability of replacement components.

- Hidden expenses like downtime, logistics, and risk of poor-quality repairs often surpass the direct cost.

- Choosing between repair vs replacement should include long-term reliability, compliance, and availability.

- OEMs can save costs with preventive strategies like component stocking and partnering with expert repair providers.

- Different industries carry different repair standards—medical and aerospace sectors typically demand higher-cost, high-reliability repairs.

📑 Table of Contents

- Key Factors That Influence PCB Repair Costs

- Hidden Costs OEMs Often Overlook

- PCB Repair vs Replacement: Cost Comparison

- Cost-Saving Strategies for OEMs

- Industry-Specific Cost Considerations

- How to Choose the Right PCB Repair Partner

- Why Choose A2Z EMS for PCB Repair and Assembly

- Wrapping Up

🔍 Key Factors That Influence PCB Repair Costs

The PCB board repair cost is never a one-size-fits-all figure. It varies significantly depending on board complexity, damage type, and the conditions under which the board operates.

🧩 Board Complexity

A basic single-layer board used in consumer electronics is cheaper to repair than a multilayer or HDI PCB designed for aerospace or medical use. More layers introduce more routing paths, which increases the complexity of locating and fixing faults.

⚠️ Nature of Failure

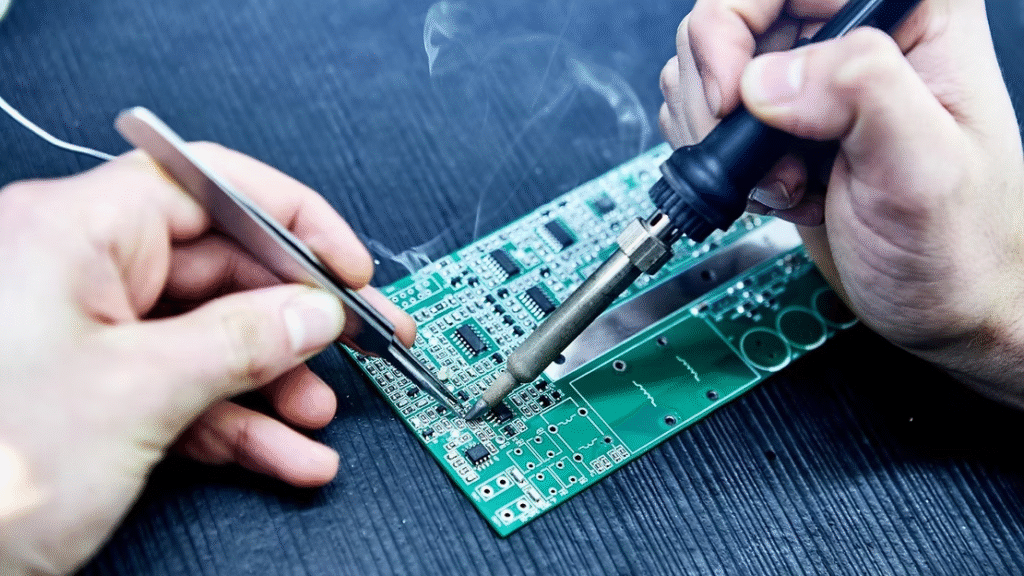

Swapping a burned-out capacitor is a quick fix. But issues involving signal integrity, short circuits, or power failures demand advanced diagnostics and longer repair cycles, increasing costs.

📦 Component Availability

If failed components are easily sourced, the PCB repair process is smoother. However, if parts are obsolete or custom-made, procurement delays and re-engineering efforts can drive up costs.

🔍 Testing & Diagnostics

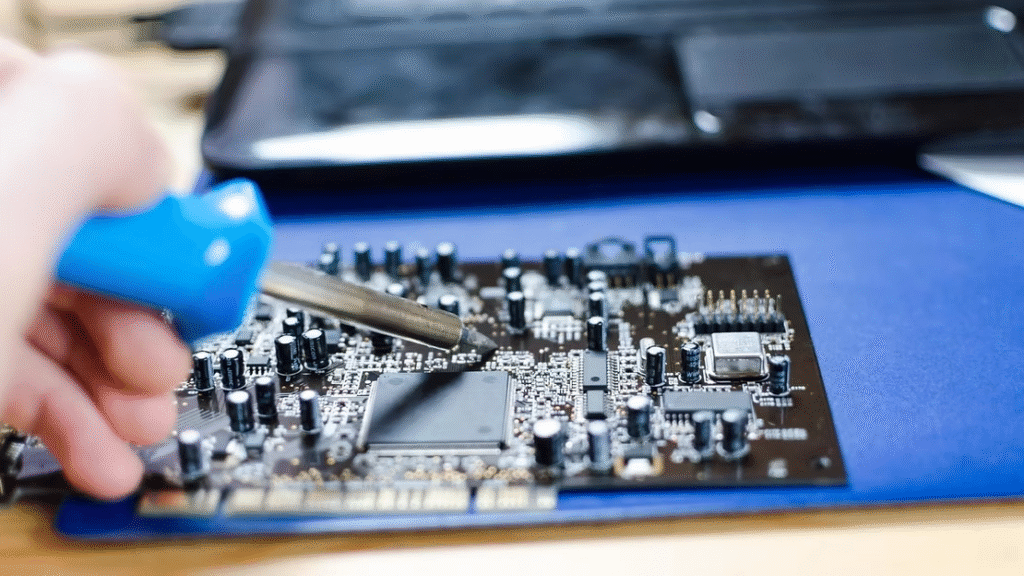

Thorough PCB troubleshooting is essential to ensure repairs fix the actual root cause. Advanced tools like thermal imaging and X-ray inspection add cost but are critical for ensuring high reliability.

🛠️ Labor & Expertise

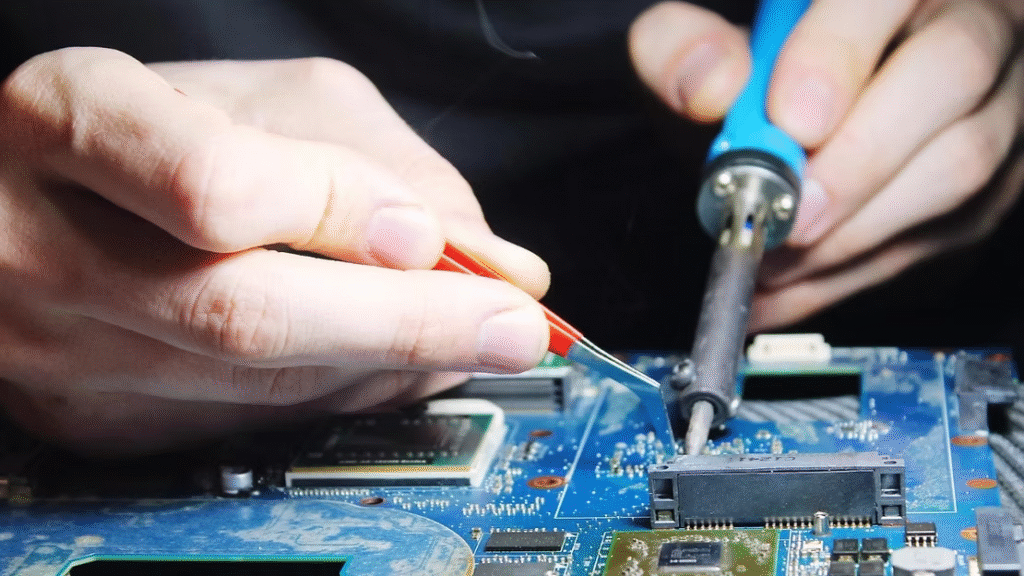

Precision repairs—especially those involving BGA reballing or fine-pitch components—require skilled technicians. Naturally, labour costs vary depending on expertise and region.

📖 Related: How Much Does PCB Assembly Cost? Breakdown & Tips to Reduce

⚠️ Hidden PCB Repair Costs OEMs Shouldn’t Ignore

While the upfront PCB repair cost might look affordable, many OEMs underestimate indirect or hidden costs that can dramatically increase the total expenditure.

⏱️ Downtime Expenses

Lost production hours can translate into thousands of dollars in missed revenue. For many OEMs, downtime is one of the most significant hidden costs.

📦 Shipping & Handling Fees

Transporting fragile PCBs safely involves special packing, insurance, and sometimes customs clearance. Cross-border shipping can introduce delays and added costs.

❌ Quality Risks

Low-cost circuit board repair services may save money short term, but if field failures occur, the resulting warranty claims and recalls can be far more damaging and costly.

🗂️ Inventory Holding

Long repair turnaround times may force OEMs to maintain backup stock, which ties up cash flow and increases holding costs.

For OEMs, understanding these hidden PCB repair costs is just as important as calculating the base repair price.

🔁 PCB Repair vs Replacement: Full Cost Comparison

When comparing PCB repair vs replacement, it often comes down to evaluating the total cost of ownership, not just the initial expense.

🔧 Repair

Repairing a PCB is usually faster and more cost-effective—especially for common issues like faulty connectors, damaged traces, or easily replaceable components. It also aligns with sustainability efforts by extending product lifespan. For instance, the AC PCB repair cost is often significantly lower than replacing the full unit.

🔁 Replacement

In some cases, replacement becomes unavoidable—particularly when the board suffers severe physical damage or includes obsolete technology and unavailable components. For mission-critical systems in aerospace or medical industries, replacement may be the only path to ensure compliance, safety, and ongoing reliability.

OEMs must weigh not only immediate costs but also long-term factors like warranty coverage, production timelines, and environmental impact.

📖 Related: How Much Does PCB Assembly Cost? A Breakdown for Small and Large Orders

💡 Smart Cost-Saving Strategies for OEMs on PCB Repairs

Managing PCB repair costs isn’t just about choosing the lowest-priced vendor—it’s about strategic planning to reduce overall risk and expense.

🔍 Preventive Maintenance

Routine inspection and testing can identify potential issues early, preventing full-scale failures that result in high repair costs.

📦 Component Stocking

Maintaining a buffer inventory of high-failure or hard-to-source parts helps avoid lead time issues and inflated pricing due to last-minute procurement.

🧪 Failure Analysis

A deep understanding of why a PCB failed helps OEMs prevent repeat issues—reducing both repair frequency and long-term costs.

🤝 Partnering with Experts

Choosing reliable providers of circuit board repair services ensures that boards are fixed right the first time, reducing rework, delays, and potential field failures.

📐 Standardization

Standardising PCB layouts and component types across products simplifies sourcing, diagnostics, and repair, all of which contribute to lower costs.

🏭 Industry-Specific PCB Repair Cost Considerations

The cost of printed circuit board repair varies widely across industries based on compliance needs, operating environments, and repair complexity.

🏥 1. Medical Devices

In the medical industry, repairs must comply with ISO 13485 and require detailed diagnostics and documentation before reuse.

- Estimated Repair Cost: $200 – $500+

- Key Cost Drivers: Compliance testing, traceability, cleanroom standards

🚆 2. Transportation Systems (Automotive, Rail, etc.)

PCBs used in transportation systems face mechanical stress, temperature swings, and dust, requiring rugged repairs.

- Estimated Repair Cost: $150 – $350

- Key Cost Drivers: Environmental durability, vibration resistance, high-reliability standards

🚀 3. Aerospace Systems

Repairs here require top-tier inspections like X-ray and thermal imaging, due to critical flight and defense applications.

- Estimated Repair Cost: $300 – $700+

- Key Cost Drivers: Advanced certifications, documentation, mission-critical reliability

🏭 4. Industrial Applications

For manufacturing and robotics, downtime equals lost revenue. PCB repairs must be fast and reliable.

- Estimated Repair Cost: $120 – $300

- Key Cost Drivers: Speed, high-power handling, part availability

💡 5. Lighting Technology

Lighting PCBs (LED drivers, smart lighting controllers) are simpler but often face heat-related damage and component aging.

- Estimated Repair Cost: $80 – $200

- Key Cost Drivers: Heat damage, power regulation, connector reliability

🛡️ 6. Defense Systems

Defense PCBs are encrypted and ruggedized. Repairs demand secure handling and traceable, certified workflows.

- Estimated Repair Cost: $400 – $800+

- Key Cost Drivers: Classified designs, secure labs, documentation-heavy processes

🔍 How to Choose the Right PCB Repair Partner

Selecting the wrong repair partner can lead to recurring faults, extended timelines, and escalating costs. OEMs should use the following checklist when evaluating a PCB troubleshooting and repair service:

- Demonstrated technical expertise and experience with both PCB troubleshooting and complex assembly

- Compliance with industry certifications such as IPC, ISO, and any sector-specific standards

- Availability of high-end diagnostics tools like X-ray analysis, AOI, and ICT testing

- Transparent, detailed pricing models with no hidden charges

- Proven track record with OEM clients in similar industries

✅ Why A2Z EMS Is the Right Partner for PCB Repair and Assembly

As a reliable electronics manufacturing company in the USA, we understand that PCB repair isn’t just about fixing hardware—it’s about protecting your brand, timelines, and product integrity.

Our printed circuit board repair services span the full lifecycle: diagnostics, component sourcing, rework, and final validation. We serve multiple industries including medical, transportation, industrial, and consumer electronics, and our repairs meet the most stringent quality benchmarks.

By partnering with A2Z EMS, OEMs benefit from more than just reduced PCB repair costs—they gain a trusted partner focused on long-term reliability, lifecycle planning, and engineering excellence.

📖 You May Also Read: How to Choose a Reliable PCB Assembly Company for Your OEM Project

🧾 Wrapping Up

For OEMs, understanding what drives PCB repair cost is essential—not just for budgeting, but for making smarter operational decisions. Factoring in hidden costs, compliance requirements, and partner expertise helps avoid costly missteps and enhances product performance.

With the right approach and a trusted partner like A2Z EMS, PCB repair transforms from an operational challenge into a strategic investment in quality and reliability.