What Trends Are Shaping Chop Saw Measuring Systems in 2025?

In 2025, the elaboration of the chop saw measuring system reflects a significant vault in perfection, effectiveness, and integration with...

In 2025, the elaboration of the chop saw measuring system reflects a significant vault in perfection, effectiveness, and integration with digital technologies. These advancements are transubstantiating how professionals approach cutting tasks, icing lesser delicacy and productivity on the job point.

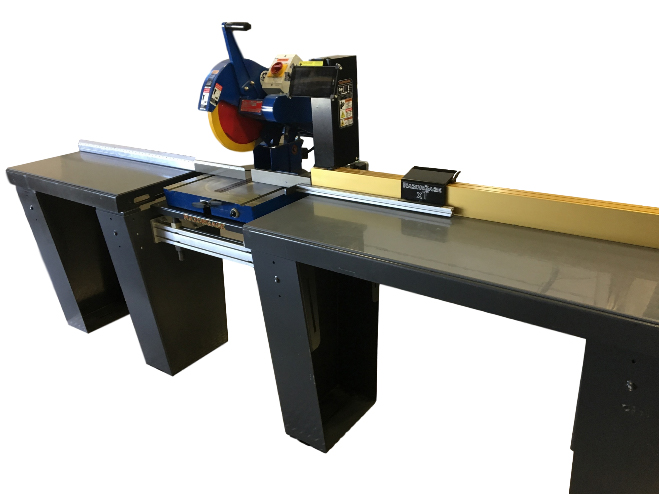

1. Integration of Digital Measurement Technologies

The objectification of digital dimension tools into chop saw systems has revolutionized the way cuts are measured and executed. Digital readouts and ray- guided systems give real- time, precise measures, reducing mortal error and the need for homemade computations. This integration enhances the overall effectiveness of cutting operations, allowing for quicker setups and more accurate cuts.

2. Wireless Connectivity and Mobile Integration

ultramodern chop saw measuring systems are decreasingly equipped with wireless connectivity features, enabling flawless integration with mobile bias and pall- grounded platforms. This connectivity allows druggies to pierce cutting plans, acclimate measures ever, and track design progress in real- time. Similar capabilities streamline workflows and ameliorate communication among platoon members, especially in large- scale systems.

3. Enhanced Material Handling Systems

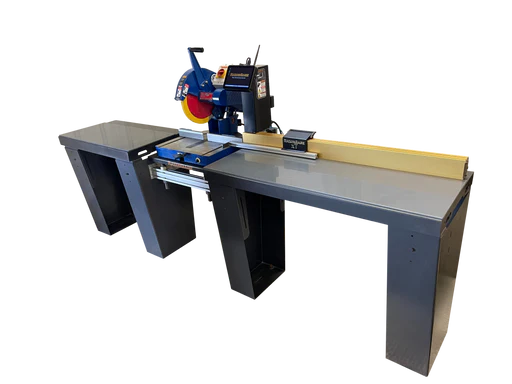

Advancements in material running have significantly impacted chop saw measuring systems. Automated feed systems and conveyors ensure that accoutrements are constantly aligned and deposited rightly before cutting. This robotization minimizes the threat of misalignment, leading to more accurate cuts and reducing material destruction.

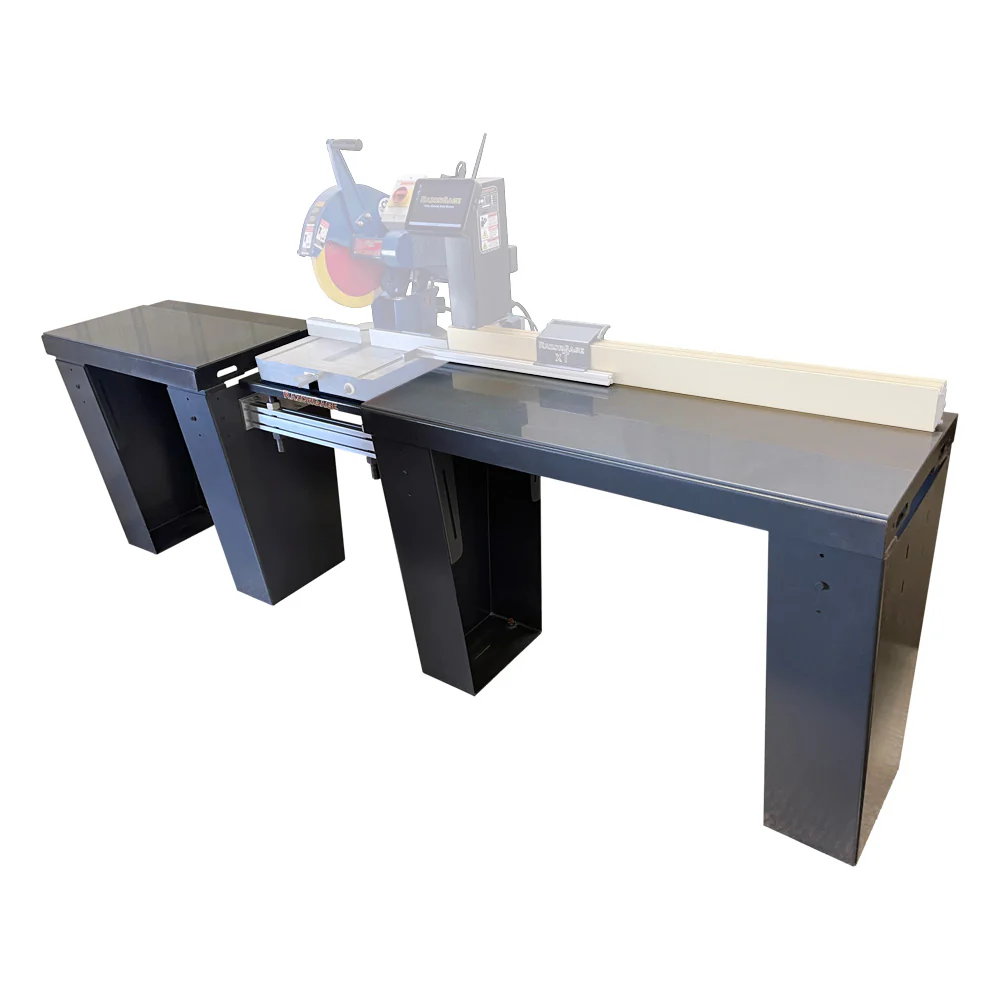

4. Compact and Movable Designs

The demand for portability in chop saw measuring systems has led to the development of further compact and featherlight designs. These movable systems maintain high perfection and continuity, making them ideal for on- point operations where space and mobility are limited. Druggies can now achieve professional- grade cuts without the need for a big outfit.

5. Stoner-Friendly Interfaces and Touchscreen Controls

To accommodate a broader range of druggies, chop saw measuring systems now feature intuitive interfaces with touchscreen controls. These stoner-friendly designs simplify the operation of complex systems, allowing indeed those with limited specialized moxie to operate the outfit effectively. The addition of customizable settings further enhances stoner experience and rigidity.

6. Integration with stoked Reality( AR) for Visualization

Augmented Reality( AR) technology is being integrated into chop saw measuring systems to give drugs with real- time visual overlays. This point allows drivers to fantasize the slice process, including measures and angles, directly onto the material. AR enhances perfection and helps in relating implicit issues before the factual slice begins, leading to more effective operations.

7. Bettered Safety Features

Safety remains a top precedence in the design of chop saw measuring systems. Enhanced safety features, similar as automatic blade thickets, exigency stop functions, and safety interlocks, are now standard. These inventions cover drivers from implicit hazards and ensure compliance with strict safety regulations, fostering a safer working terrain.

8. Energy Efficiency and Sustainability

With growing environmental enterprises, there’s a drive towards energy-effective and sustainable chop saw measuring systems. Manufacturers are fastening on reducing power consumption and exercising eco-friendly accoutrements in the construction of these systems. Similar sweats contribute to lower functional costs and a reduced carbon footmark.

9. Advanced Estimation and Conservation Tools

Regular estimation and conservation are pivotal for maintaining the delicacy and life of chop saw measuring systems. Advanced individual tools and automated estimation processes are being incorporated into these systems, allowing for quicker identification of issues and reducing time-out. Prophetic conservation features also help in anticipating implicit problems before they do.

10. Integration with Cut List Optimization Software

The community between chop saw measuring systems and cut list optimization software has come more pronounced. These software results dissect design conditions and induce optimized cutting plans that minimize material waste and ameliorate effectiveness. Integration with measuring systems ensures that the optimized plans are executed directly, leading to cost savings and enhanced productivity.

In conclusion, the trends shaping chop saw measuring systems in 2025 highlight a shift towards lesser perfection, effectiveness, and integration with digital technologies. The relinquishment of digital dimension tools, wireless connectivity, and stoner-friendly interfaces are transubstantiating how cutting tasks are approached. Also, the focus on safety, energy effectiveness, and integration with cut list optimization software underscores the assiduity’s commitment to invention and sustainability. As these trends continue to evolve, professionals can anticipate indeed more advanced and effective chop saw measuring systems in the future.