2024 Maintenance Tech Progression 06.25.2024.pdf : Key Trends Shaping the Future

Maintenance will undergo an extensive transformation in 2024 through innovative technologies and developing industrial practices. Such critical times call for...

Maintenance will undergo an extensive transformation in 2024 through innovative technologies and developing industrial practices. Such critical times call for technology to guide businesses toward operational efficiency while lowering costs and building sustainability. The primary elements that will reshape the industry are documented in the 2024 Maintenance Tech Progression 06.25.2024.pdf document. This research examines recent industry changes that include predictive maintenance adoption alongside automation tools and sustainable procedures as well as workforce knowledge upgrades and cybersecurity advancements along with forthcoming technology improvements.

I. The Rise of Predictive Maintenance in 2024

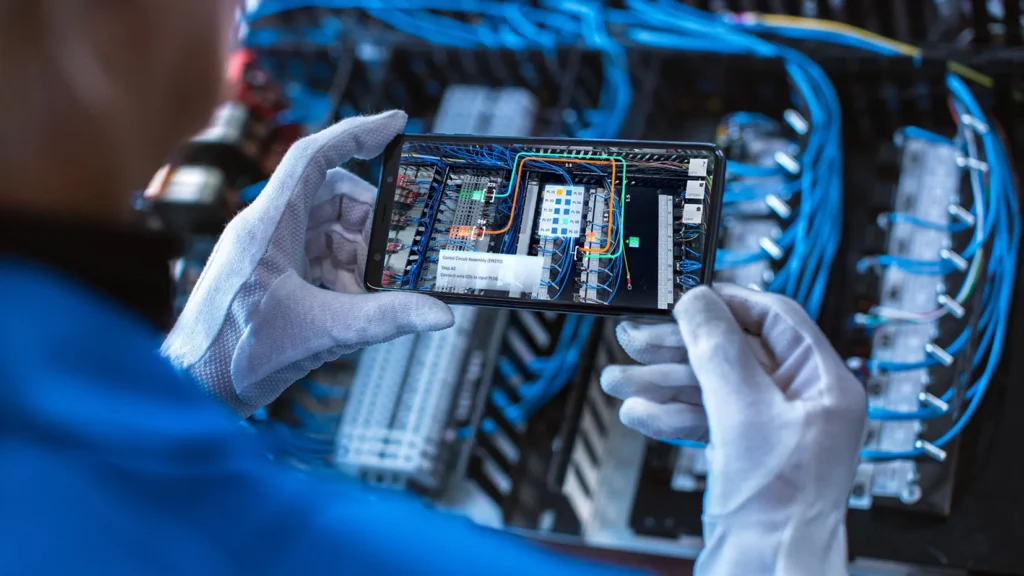

Predictive maintenance now stands as a revolutionary strategy for maintaining modern systems. Organizations can keep track of equipment condition through real-time monitoring combined with the Internet of Things (IoT) and Artificial Intelligence (AI) and Cloud Platforms to foresee failure onset points allowing for proactive maintenance.

What is Predictive Maintenance?

Etaura analyzes data from sensory equipment in machinery to evaluate device health status while forecasting the next component failure point. By using data from operational equipment predictive maintenance enables companies to establish proper maintenance intervals that reflect actual device conditions. By using this method companies decrease equipment downtime thereby preventing unneeded maintenance costs and saving money in the process.

Key Technologies Enabling Predictive Maintenance:

IoT (Internet of Things): The built-in monitoring sensors of equipment measure temperature and vibration magnitude while detecting changes in pressure. The collected data transfers from sensors into a central analytical system in real-time.

AI (Artificial Intelligence): Through AI algorithms IoT sensors send large datasets into analysis so AI identifies abnormal patterns leading to potential equipment issues.

Cloud Platforms: Through cloud platforms organizations can establish real-time data repositories combined with remote monitoring capabilities to achieve scalable and accessible predictive maintenance solutions.

Benefits of Predictive Maintenance:

Reduced Downtime: Predictive maintenance lets maintenance crews handle equipment breakdowns before they happen which cuts down on unexpected operational interruptions.

Cost Savings: Companies can stretch out their machinery longevity and decrease repair costs by conducting maintenance only when problems are detected.

Increased Efficiency: The combination between minimized equipment breakdowns and optimized repair plans optimizes operational operation efficiency levels.

II. Automation Tools Revolutionizing Maintenance Operations

Automation currently revolutionizes the way maintenance functions operate to enhance technicians’ capabilities for high-precision work along with rapid execution and trained consistency. Advanced automated tools now transform how businesses perform standard maintenance operations along with intricate ones.

Overview of the Role of Automation in Maintenance

Maintenance automation means using technological systems to fulfill duties earlier executed manually. Equipment performance monitoring through autonomous lubrication systems and robotic inspections and machine learning algorithms operates to adjust machinery control.

Emerging Automated Maintenance Tools

Robotic Inspections: Modern robotic technologies can access inspection areas that humans could not reach before. Robots examine equipment through connected sensors and cameras which combine artificial intelligence to monitor for issues like corrosion, leaks and cracks.

Autonomous Lubrication Systems

Through automated operations these systems deliver lubrication at the right times thus minimizing equipment damage while avoiding system breakdowns from inadequate lubrication.

Key Challenges in Implementing Automation

The advantages of automated systems continue to grow yet their practical adoption still presents several implementation hurdles. Three main obstacles in technology implementation involve the expensive initial expenses and staff requirements for training and system compatibility continuation. Planning strategically alongside scalable system selections will help resolve identified implementation obstacles.

III. Sustainable Maintenance Practices: Eco-Friendly Solutions in 2024

Trade and industry sectors make sustainability their foundational focus and maintenance operations demonstrate no exception. Refreshing maintenance techniques not only assist businesses in following environmental regulations but simultaneously yield lasting financial advantages.

Growing Importance of Sustainability in Maintenance Practices:

Firms are dramatically adopting sustainable maintenance practices in 2024 to minimize their environmental footprint. Energy-saving equipment reception and waste minimization alongside green material selection are key components of sustainable maintenance practice.

Adoption of Eco-Friendly Solutions:

Biodegradable Lubricants: Products used for lubrication pose environmental threats but businesses now have access to earth-friendly alternative products. These environmentally friendly lubricants decompose into the environment without requiring toxic chemicals.

Recycling and Waste Reduction: Maintenance operations today implement recycling processes that both minimize resource consumption and waste production.

Benefits of Sustainable Maintenance Practices:

Cost Savings: Expanding into environmentally responsible solutions leads to both long-term cost reductions and decreased environmental violation penalties through energy savings.

Improved Environmental Impact: Companies meet sustainability goals through sustainable practices which decrease their carbon emissions and pollution production.

Read More : Steven Moore Lanier Tech Collage

IV. Organizations need to ready their maintenance technology expertise for upcoming changes.

The continued progression of maintenance technology creates growing needs for workforce members who possess capabilities to handle such tools effectively. Success within the maintenance industry now demands fundamental adaptation capabilities for new technologies as well as systems.

The Importance of Workforce Development and Training:

The implementation of advanced technologies requires business investment in workforce training programs to ensure an organized transition. Learning programs for Artificial Intelligence and robotic systems together with predictive maintenance algorithms are essential for workforce readiness in upcoming maintenance practices.

Key Areas of Upskilling:

AI and Machine Learning

Employees must grasp the operational principles of AI tools together with the interpretation of these systems’ generated data output.

Automated Systems: The increasing presence of automated systems demands that workers receive training to handle and resolve these systems.

Advanced Maintenance Technologies

The maintenance force requires complete familiarity with new predictive maintenance systems and robotic inspection devices which operate as modern tools and technologies.

Collaboration Between Industry and Academia

The foundation of addressing skill gaps depends on active collaboration between institutions which teach and businesses which need trained personnel. The workforce development combines academic programs delivered by universities and technical schools with hands-on experiences available through participating companies and apprenticeships programs.

V. Cybersecurity Challenges in Maintenance Technology

The increasing popularity of IoT together with cloud platforms joined by automated systems hereby created an urgent need for cybersecurity in maintenance technology. Systems’ integrity together with data protection represents essential needs for running operations both efficiently and safely.

Rising Cybersecurity Risks:

Maintaining network security becomes increasingly difficult because the rising number of digital devices connecting online. IoT devices together with cloud computing platforms expose maintenance operations to multiple threats including data breaches and malware and ransomware intrusions.

Common Threats:

Data Breaches

Successful hackers intercept operational data which endangers the structural elements of maintenance documentation together with procedural methods.

Implementing Robust Cybersecurity Measures

Successful risk reduction depends on business adoption of robust cybersecurity protocols. Organizations must utilize three key steps to protect data: they need to encrypt information and perform two-step authentication and maintain consistent updates for security patches.

VI. The Future of Maintenance Technology: Trends to Watch

Forward-looking maintenance technology reveals numerous exciting developments that confront the industry going forward. Businesses who continue operating will find combined systems of automation alongside AI technology as well as IoT solutions and enhanced sustainability alongside fortified cybersecurity platforms.

Exploration of Upcoming Advancements

Present-day predictions indicate the upcoming years will advance predictive maintenance by providing better algorithms together with increased processing speed. A new generation of automated tools will advance their capabilities through enhanced self-healing systems and basic diagnostic functions.

Expansion of Automation and AI

Three driverless technologies will dominate maintenance operation through 2024 by expanding machine capability to perform complex operations independently from human supervision.

Predictions for Sustainable and Secure Practices

The key driver behind new technology development will become sustainability because companies move towards embracing green practices. Business entities will make cyber protection their main focus through advancements in threat detection tools combined with encryption solutions.

VII. Conclusion

The 2024 Maintenance Tech Progression 06.25.2024.pdf offers an extensive evaluation of the main technological developments which will influence maintenance technology in the future. Companies in the industry pursue a transformation through predictive maintenance and automation alongside sustainability and cybersecurity pursuits. The future success of businesses depends on their adoption of these advancements because it brings increased operational efficiency and lowered expenses and better market positioning. The maintenance sector will find ongoing advantage from technological advancement that emerges through cooperative relationships between technology providers as well as educational institutions and industry leaders.

FAQs

What does the “2024 Maintenance Tech Progression” PDF cover?

The “2024 Maintenance Tech Progression” PDF outlines the career progression, skill development, and certification paths for maintenance technicians in the year 2024. It provides a roadmap for professionals looking to advance their careers in maintenance, detailing key steps and requirements for moving up the career ladder.

How can the “2024 Maintenance Tech Progression” guide help me in my career?

The “2024 Maintenance Tech Progression” guide is designed to help maintenance professionals understand the key steps to advance in their careers. It provides clear recommendations for skill-building, industry certifications, and ways to improve job performance. Whether you’re just starting or looking to further your career, this guide offers practical advice for career growth in the field.

How do I access the “2024 Maintenance Tech Progression” PDF on Pro-Reed.com?

To access the “2024 Maintenance Tech Progression” PDF, visit the Pro-Reed.com website and navigate to the relevant section for tech-related resources or career progression guides. There, you will find the latest version of the document, available for download or viewing. Make sure to check the publication date to ensure you’re viewing the most current edition.

Why is career progression important for maintenance techs in 2024?

Career progression for 2024 maintenance tech progression 06.25.2024.pdf is vital due to the evolving nature of the technology industry. As companies adopt newer systems and equipment, technicians need to stay updated with the latest tools, techniques, and certifications. This not only improves job security but also opens up higher-paying roles and leadership opportunities in the field.