Rotary Sealers for Medical and Industrial Packaging – Precision & Reliability

Sealing technology is a crucial component of packaging, particularly in industries where quality standards are non-negotiable.

Packaging plays a critical role in both medical and industrial applications, where safety and reliability cannot be compromised. In the medical field, sealed pouches often protect devices and instruments from contamination, while in industrial settings, packaging ensures product integrity during transport and storage. A rotary sealer is one of the most effective tools for achieving this. Known for its consistency and speed, it provides precise sealing that helps meet demanding quality standards. This article examines how rotary sealer technology enables safe, efficient, and reliable packaging across various industries.

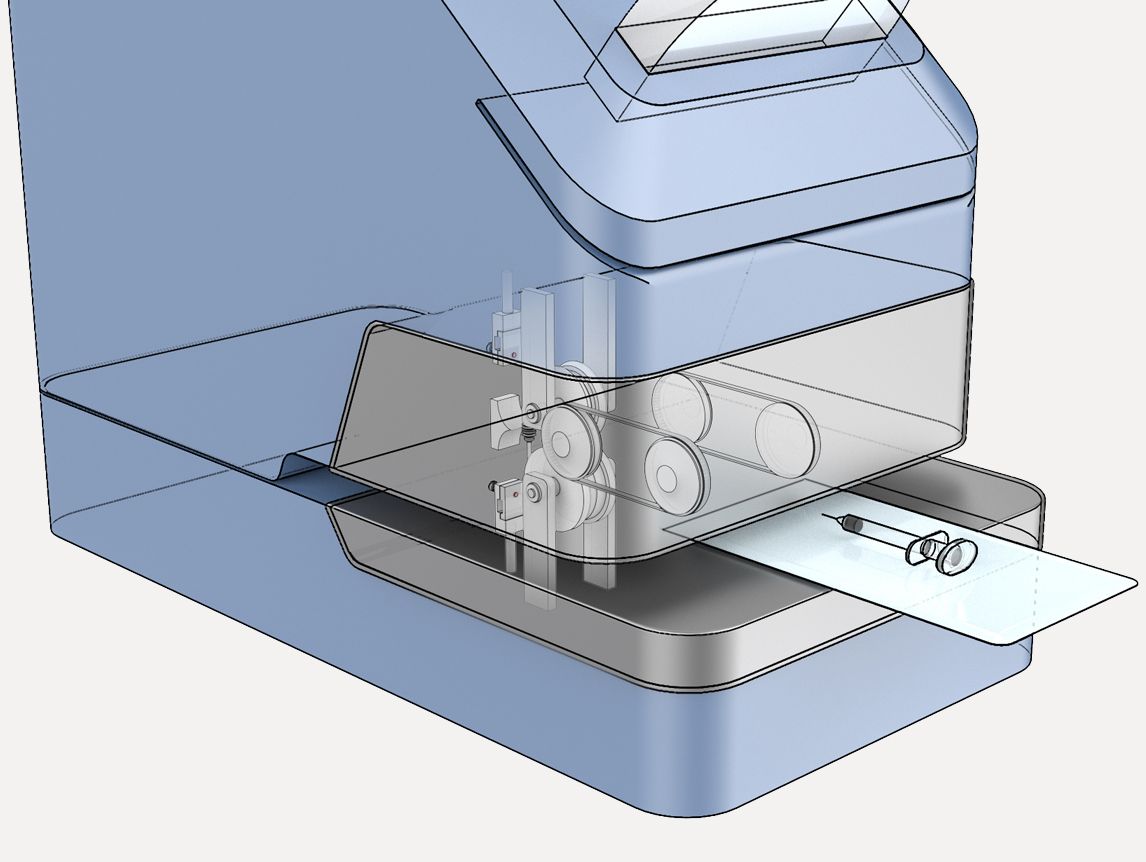

What Is a Rotary Sealer?

To begin, it is important to understand the function. A rotary sealer uses heated bands and pressure to create continuous, airtight seals on pouches or bags. Unlike impulse or jaw-type sealers, rotary systems continuously pull materials through, ensuring uniform sealing without interruption. This makes them highly efficient for high-volume operations.

Why Precision Matters in Medical and Industrial Packaging

Accuracy in sealing is critical for two reasons.

- In medical packaging, sterility must remain intact until the product is used. Even a slight compromise in the seal can lead to contamination.

- In industrial packaging, consistent seals prevent leaks, protect products, and reduce wastage.

A rotary sealer achieves precision by controlling heat, pressure, and speed, resulting in dependable and repeatable outcomes.

Core Features and Benefits

Rotary sealers provide several advantages that make them the preferred choice.

- Consistency: Each seal is produced with controlled settings, ensuring uniformity and eliminating variation.

- Speed: Continuous sealing supports higher output compared to single-pouch sealers.

- Validation Support: Many models comply with ISO and FDA packaging standards.

- Printing Capabilities: Some machines print expiry dates, barcodes, or lot numbers directly on the pouch.

- Cleanroom Compatibility: Stainless steel designs ensure hygienic use in sterile environments.

Together, these features make rotary sealers an investment in both quality and compliance.

Rotary Sealer vs Other Sealing Methods

It is helpful to compare rotary sealers with alternatives.

- Jaw-type sealers: Offer reasonable control but are slower and suitable for smaller volumes.

- Impulse sealers: Heat only during sealing, but they can struggle with multi-layer materials.

- Form-Fill-Seal systems: High output but require greater setup and are less flexible for varied packaging.

In comparison, a rotary sealer strikes a balance between speed, precision, and adaptability.

Applications Across Industries

Rotary sealers serve multiple sectors.

- Medical devices and instruments: Maintain sterility and patient safety.

- Pharmaceutical packaging: Ensure accurate, contamination-free sealing.

- Industrial goods: Provide secure, tamper-resistant packaging for transport and storage.

This broad applicability highlights their importance across production lines.

Conclusion

Sealing technology is a crucial component of packaging, particularly in industries where quality standards are non-negotiable. A rotary sealer delivers precision and reliability, enabling businesses to meet regulatory requirements while improving efficiency. In healthcare, it safeguards sterility, and in industrial packaging, it ensures product protection and consistency. By adopting rotary sealing solutions, organisations can reduce errors, improve output, and maintain the integrity of their products. In both medical and industrial environments, the role of rotary sealers remains vital, offering a dependable solution for modern packaging demands.